Getting Metal Out of Spices

By Paul Fears | 21 June 2021

Most households have a collection of spices in one of their kitchen cupboards. Adding spices to food when cooking is not only a common practice, but essential for most culinary enthusiasts. But how are the spices processed and prepared?

Spices are commonly grown in the tropical regions of the world, with some thriving in the cool misty highlands. Many of the seed spices come from more temperate areas, such as coriander seed, which is grown in Northern India, Africa and the wheat producing areas of South Australia and Western New South Wales.

The nature of the location, how the spices are collected and the method of processing and converting into powders, mean that there is a high risk of metal contamination. Most spice plants use a series of Magnetic Separators and Metal Detectors to remove and detect any problematic metal. Indeed, many UK supermarkets and food retailers (e.g. Marks & Spencer) have strict guidelines on the use of metal removal equipment.

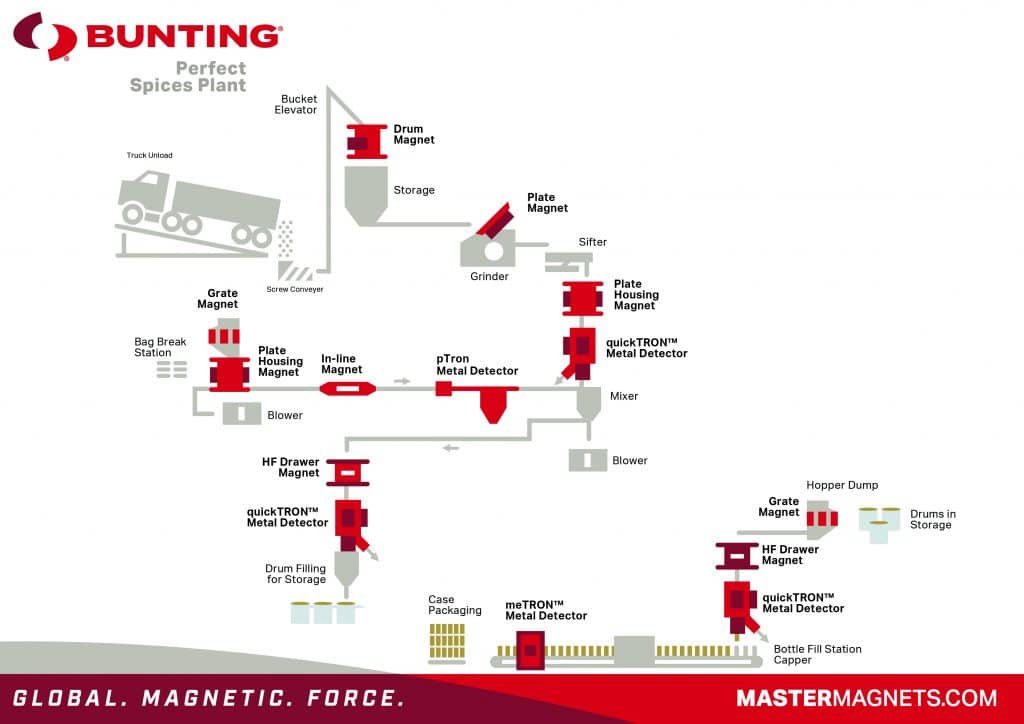

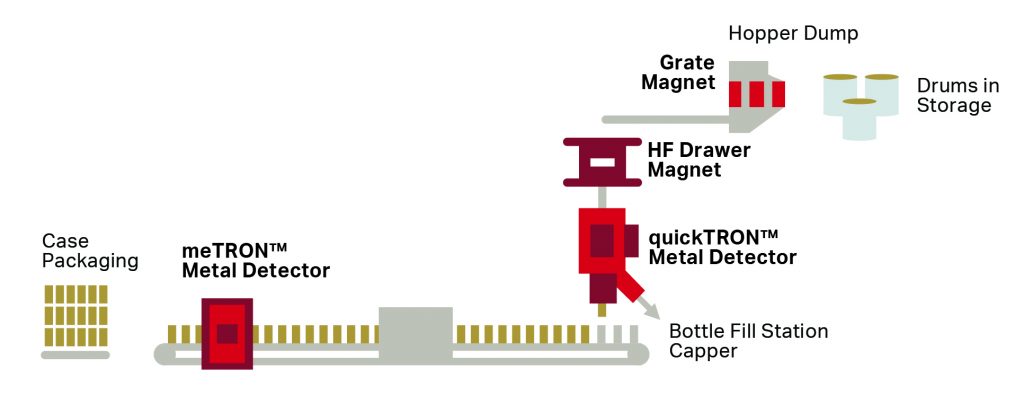

The plant shown in the flowsheet is a generalisation of a typical spice producing operation and highlights suitable locations for both Magnetic Separators and Metal Detectors.

Delivery, Grinding & Screening

The initial stages of processing the spices involves the delivery of the farmed spices, the grinding of the seeds into powder, and the screening of the powder to remove any oversized particles.

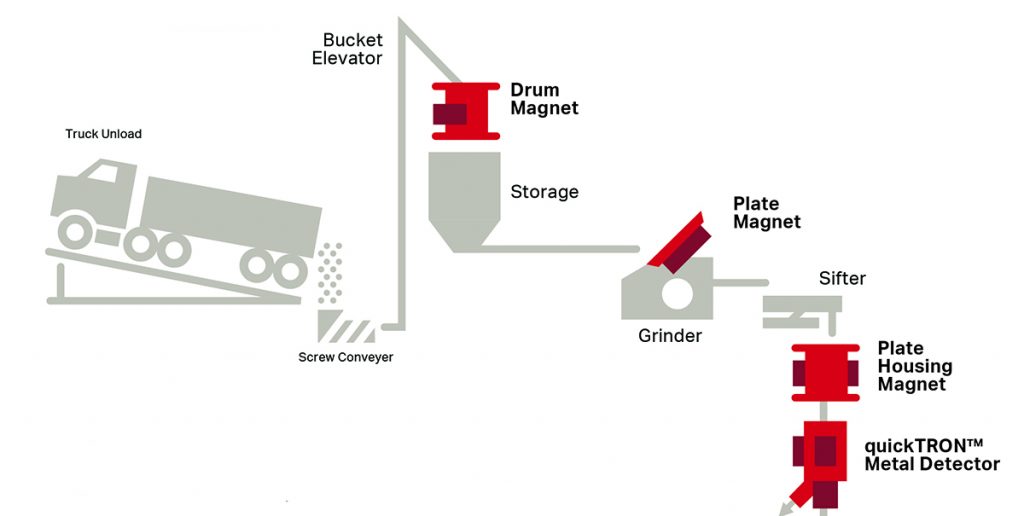

Step 1 – On Delivery

Ideally, it is always best to remove any rogue metal before it enters the process. At this stage, any metal contamination tends to be larger in size and easier to separate. For automated cleaning, the delivered spices are passed over a Drum Magnet, either with standard strength ceramic ferrite magnets or high-intensity rare earth magnets. This automatically separates magnetically susceptible metal prior to the spices moving on to initial storage.

- Technical Product Information: Drum Magnets

Step 2 – Prior to Grinding

Grinding the spice seeds into the correct particle size range is a critical stage in the process. The grinder is also vulnerable to damage from metal contamination, which is costly and affects productivity. Although the Drum Magnet will have removed the majority of ferrous metal, the spice seeds are fed over the face of a high-intensity rare earth Plate Magnet, which captures and holds any remaining ferrous metal contamination.

- Technical Product Information: Plate Magnets

Step 3 – Post Grinding and Screening

The process of grinding liberates any entrapped metal, and also there is general wear and tear to both the grinder and following shifter/screen which introduces fine iron back into the process. Subsequently, when the screened spices leave the sifter, they pass through either a combination of a Plate Housing Magnet followed by a quickTRON Metal Detector or just the metal detector.

The Plate Housing Magnet has an open throat, eliminating any potential flow restriction, with two high-strength facing Plate Magnets. As material falls through under gravity, ferrous metal is attracted to the face of the Plate Magnet and held until manually cleaned.

The quickTRON Metal Detector also receives the spices via gravity, identifying and automatically rejecting metal contamination including non-ferrous metals.

- Technical Product Information: quickTRON Metal Detector

Externally Processed Spices

In plants preparing spices mixes (e.g. for sauces), the externally-sourced spices also need to pass through a series of magnetic separators and metal detectors to ensure that no rogue metal is introduced back into the process.

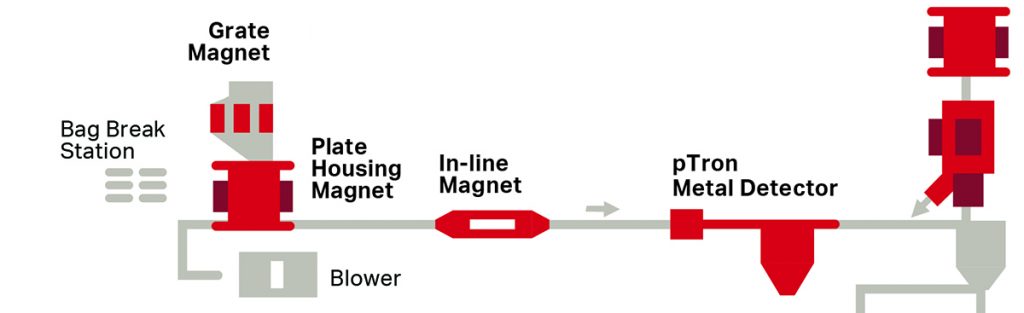

Step 4 – Bag Breaking

The externally prepared spices are commonly delivered in bags which need breaking and feeding into the process. This is a point of high risk for metal contamination and the received spices pass through a Grate Magnet, positioned in a hopper. The Grate Magnet features high-intensity rare earth Tube Magnets which capture and hold fine, small and large magnetically susceptible metals. For spices with a larger particle size range and if not 100% dry, a Plate Housing Magnet with the unrestricted throat would separate larger tramp metal.

- Technical Product Information: Grate Magnet

Step 5 -Pneumatic Feed to Mixer

The received spices are then pneumatically conveyed to the mixer. Either in addition to the earlier magnetic separators, or in preference, two metal separators designed specifically for pneumatic lines are mounted prior to the mixer. The Inline Magnet, with a high-strength rare earth Plate Magnet mounted on one side, removes tramp ferrous metal contamination.

- Technical Product Information: Inline Magnets

This is followed by a p-TRON Metal Detector which detects and automatically removes both ferrous and non-ferrous metal contaminants.

- Technical Product Information: p-TRON Metal Detector

Post Mixing

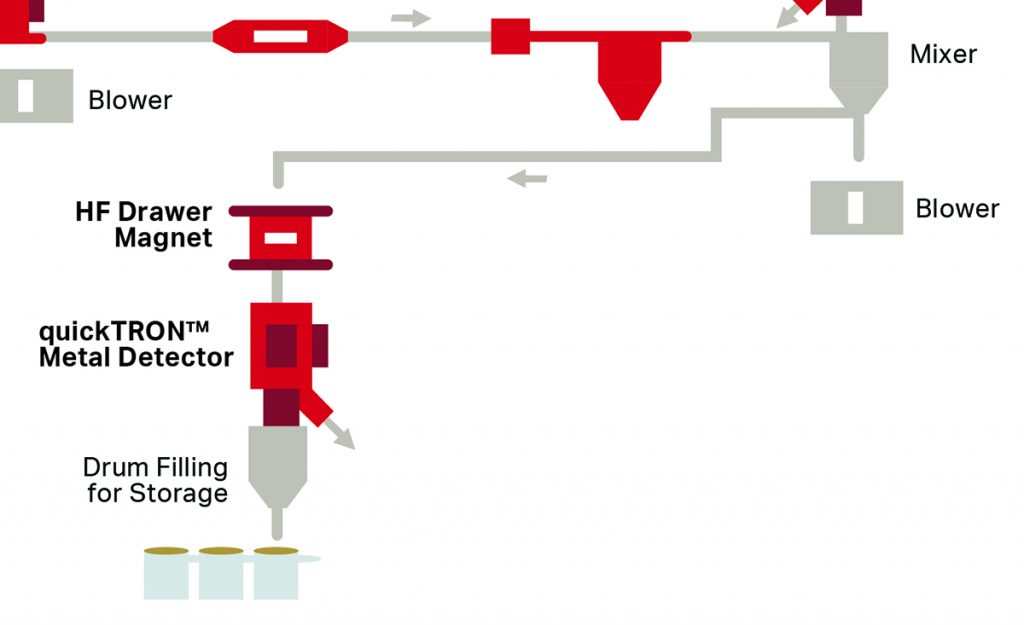

Step 6 – Prior to Drum Filling for Storage

The internally processed spices and external-sourced spices are then mixed into a specific mix or blend, before being packed into drums for storage. As wear to the mixer or other process plant can introduce metal into the process, the combined spice mix is gravity-fed through a Drawer Magnet (with high-strength Neodymium Tube Magnets) and quickTRON Metal Detector.

- Technical Product Information: Drawer Magnets

Prior to Final Packaging

Step 7 – Final Check

When undertaking final packing prior to despatch of the finished spices or spice mix, the storage drums are emptied into a filling station. As this is the final stage prior to packing of the spices into the finished packaging (e.g. a spice jar, plastic sleeve within a cardboard box, etc), there is a last check for metal contamination.

Either a Grate Magnet, mounted in a hopper, or a Drawer Magnet removes fine and small ferrous metal contamination using high-strength rare earth Tube Magnets. Once the ferrous metals are removed, a quickTRON Metal Detector ejects any remaining metal, both ferrous and non-ferrous.

Despite the series of magnetic separators and metal detectors within the plant, many purchasers, especially large UK-based supermarkets, demand that all packed products pass through a conveyor mounted Metal Detector such as the meTRON Metal Detector. This detects any metal in the final packed product, preventing any contaminated spice jar reaching the consumer.

- Technical Product Information: Conveyor mounted meTRON Tunnel Metal Detector

Complete Protection

The multiple stages of metal separation with both magnetic separators and metal detectors may appear excessive, but is necessary due to the nature of the process. Metal contamination, in a wide variety of forms, gets introduced at any stage in the process, especially after grinding and mixing. Installing specific designs of Magnetic Separators and Metal Detectors at different locations within the process ensures that the end product is metal-free and eliminates costly metal damage to processing equipment.

Related Metal-in-Food Technical Articles

For further information on Magnetic Separators and Metal Detectors used in removing metal contamination from spices or for any food processing application, please visit our website or contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Lead image (Spices in the market) by Peter H from Pixabay