15 Magnetic Liquid Traps Capture Iron in Orange Juice

By Paul Fears | 26 August 2020

Over an 18 month period, Bunting supplied 15 Magnetic Liquid Traps to Spanish citrus juice producers. The magnetic separators have ultra-strong Rare Earth Magnets which attract, hold and thus separate any fine iron present in the fruit juice.

Fine Iron Contamination in Orange Juice

Although, to many, the thought of food contaminated by metal is shocking, it is actually very common. The origin of metal contamination such as fine iron is often difficult to pinpoint. In the production of fruit juices, typical sources of fine iron contamination include:

- During harvesting and picking: Dirt often has a magnetic property and can be carried on the surface of the fruit;

- During transportation: Even if the fruit is collected in plastic containers, metal contamination can be introduced from the transport (e.g. rust, metal dust, dirt).

- During processing: The process of extracting the juice from the orange or grapefruit involves several stages of slicing, squeezing and processing. Wear to the process equipment will produce fine metal contamination.

Capturing Metal Contamination

Fine iron is difficult to capture. In operation, the fine iron present in the fruit juice needs to flow close to or over the surface of high-strength Neodymium Rare Earth magnets.

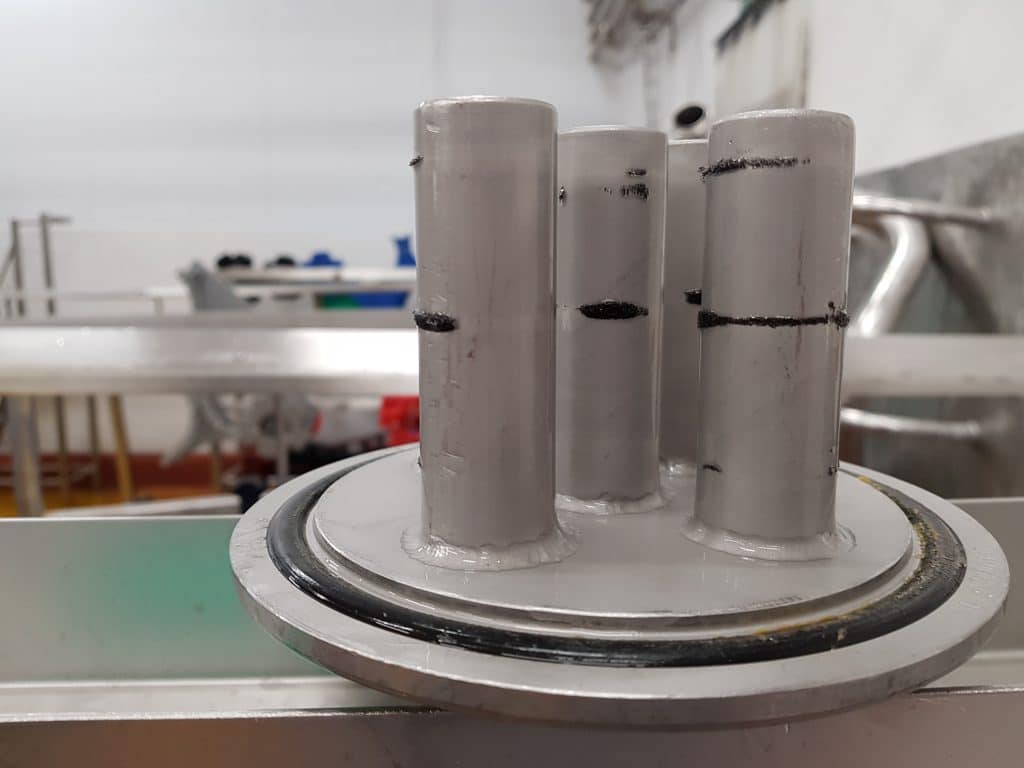

The design of Bunting’s Magnetic Liquid Traps ensures maximum contact of the juice with the magnets by forcing the liquid through a tightly spaced arrangement of Tube Magnets. The fine iron and any other ferrous metal contamination (e.g. nails, nuts, rust, etc) is attracted to the surface of the magnets and held. The magnetic strength ensures that the captured fine iron is trapped and not released back into the juice.

The captured metal is regularly cleaned from the Tube Magnets to maintain maximum separation performance. On a designated frequency, determined by the level of contamination, the lid of the Magnetic Liquid Trap (to which the Tube Magnets are attached) is removed from the body and captured fine iron is removed manually using a cloth.

- Technical Product Information: Magnetic Liquid Traps

Protecting Welds Against Acidity

Fruit juices are naturally acidic, ranging between 2.00 and 4.80. This level of acid corrodes standard welds. The Tube Magnets in the Magnetic Liquid Trap are welded onto the lid in compliance with food grade standards.

However, when exposed to acidic liquids, standard welding materials pit and corrode over time. Eventually, the weld is eaten away, allowing the ingress of liquid into the Tube Magnet casing. This catastrophically damages the magnets, causing them to swell and lose their magnetic properties. As the magnet swells, it can also split the outer casing.

The Bunting Magnetic Liquid Traps are manufactured with special welds to ensure such damage does not occur.

Magnetic Separators for the Food Industry

Magnetic Liquid Traps are part of the wide range of magnetic separators designed for use in the food industry. The range includes designs for wet and dry products, as well as belt, gravity and pneumatically conveyed foodstuffs.

Related Metal-in-Food Technical Articles

For further information on Magnetic Separators used in removing metal contamination from fruit juices or for any food processing application, please visit our website or contact us on:

Email: Gordon Kerr at GKerr@buntingmagnetics.com

Telephone: +44 (0) 1527 65858

Follow us on social media