Grain Boundary Diffusion Technology

By Paul Fears | 23 August 2018

Neodymium (NdeFeB) Rare Earth Magnets are used throughout industry and, as demand increases from the Energy, Automotive, Aerospace and Down Hole markets, the drive is towards producing magnets that have the highest magnetic energy under the harshest of conditions such as:

- Hot environments;

- High Reverse Field Environments;

- High-Speed High Induced losses environments.

These are typical applications where the Samarium Cobalt (SmCo) Rare Earth Magnet has been traditionally preferred to NdFeB, but with the rise in cost of Cobalt and the current high price of Dysprosium (Dy), there has been a growing demand for a better performing NdFeB.

Magnets Handling High Temperatures

The temperature of a permanent magnet in a motor could rise above 150 deg C under maximum load conditions, which would cause a magnet with lower intrinsic coercivity to become de-magnetised. To satisfy the higher temperature requirement, the intrinsic coercivity of magnet could be increased by adding the heavy rare earth element Dysprosium.

With added Dysprosium, the magnet will suffer less loss in the same temperature condition, but will be more expensive and have a lower residual magnetic induction or magnetic remanence, otherwise known as Br and BHmax (if the original grade was greater than 35MGOe).

Grain Boundary Diffusion (GBD) Technology

Rather than add expensive Dysprosium to the total mix and waste it in the middle of a grain, new technology allows the Dysprosium to diffuse from the surface around all of the the grain boundaries. In Grain Boundary Diffusion (GBD) technology, when the heat treatment temperature is higher than the melting point of Nd-rich phase, then the Dysprosium/Terbium compound on the magnet’s surface can penetrate into the magnet through its grain boundary.

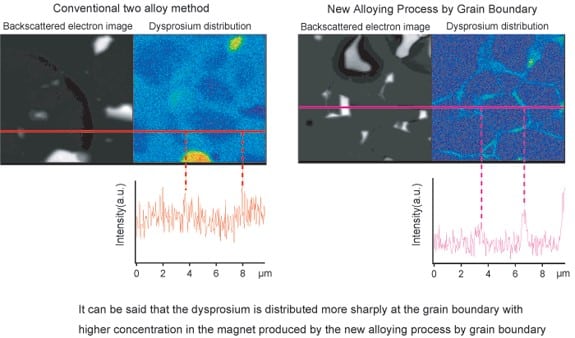

The image on the left shows the light blue as Dysprosium and the dark blue as NdFeB. With Grain Boundary Diffusion the Dysprosium in the right picture is only at the grain boundaries, where it is needed.

By reducing the Dysprosium in the grain and ensuring it is only at the boundary the Br and BHmax remain unchanged and less Dysprosium is used in the production process, reducing the manufacturing cost.

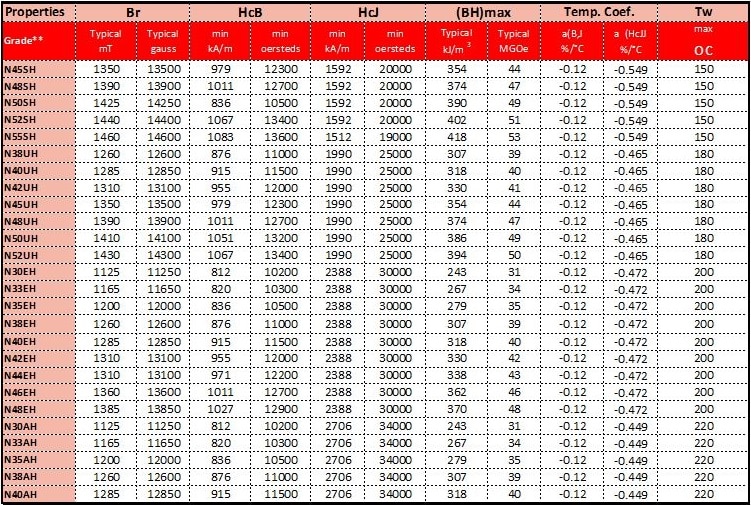

This new technology is being used by Bunting in the UK to produce a range of grades of higher performing NbFeB Rare Earth Magnets, which are listed in the table below. The grade is proportional the magnet shape and size.

Related Technical Article

Magnet and Magnet Assembly Design

Bunting designs and manufactures a wide range of magnet setters, magnetisers, magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media