The Brunel Solar Team Technically Supported by Matthew Swallow

By Paul Fears | 07 May 2024

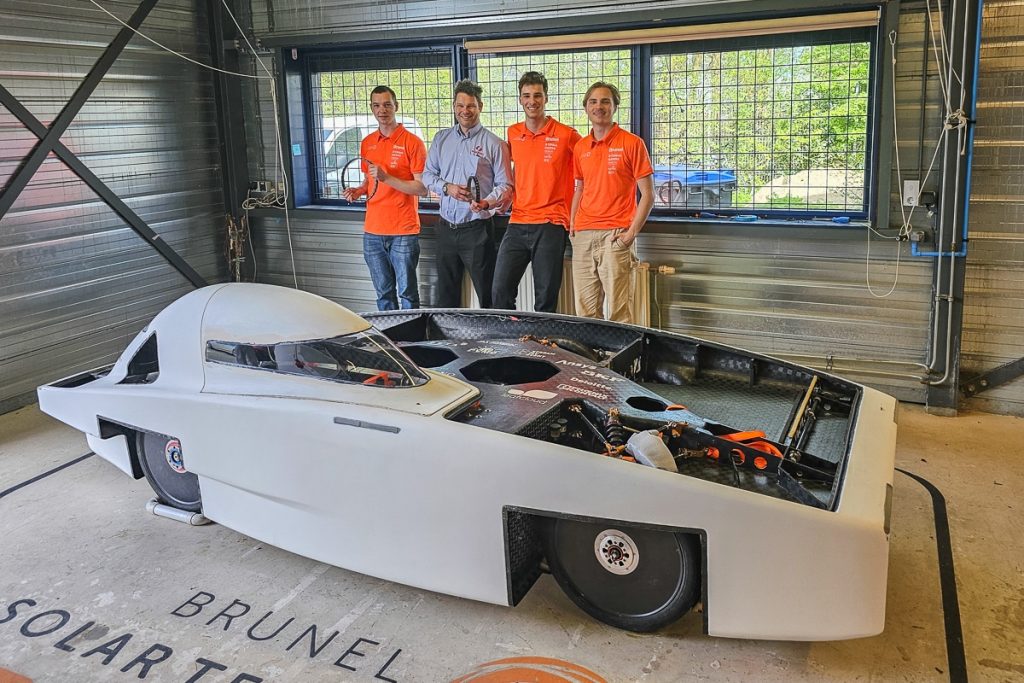

Matthew Swallow, Bunting’s Technical Product Manager, recently visited the Brunel Solar Team in The Netherlands as part of Bunting’s ongoing technical support on the solar car development project.

Bunting is supporting the Brunel Solar Team with specialist magnets and technical support in the development of their Nuna 12S solar powered car. The Nuna 12S will complete with other teams in the 16th Sasol Solar Challenge (September 2024), driving from Johannesburg to Cape Town in South Africa.

Matthew reports on his exciting and successful trip.

“As I said in my recent interview for the BBC, ‘My Job is Brilliant!’

It really is!

I have often thought that what I love doing is solving problems, but, on reflection, it is not just that. These problems are not mine to solve; they are my customer’s and colleague’s problems with which they need help and support. Helping people is key to job satisfaction and it is no surprise then that when I solve problems, I am really helping people.

Bunting is here to help anyone with a magnetic application. We might try to make improvements, make it work, or simply make it!

So, when the Brunel Solar Team got in touch to ask for help, we did what we always do and said ‘Yes’!

The team’s timeline is tight, with the competition at a fixed point in time, and the student engineers have less than one year to design, build and test their solar car ready for the race across South Africa.

The initial discussions focused on some of the problems of the entry in the previous year and this experience very much coloured their view. Bonding magnets to anything is about actually bonding the magnet material to the substrate and not a coating to a substrate as this can lead to magnets coming loose during application. It is also about choosing the right adhesive, getting the surface prepared and then applying the right amount of force while the adhesive cures.

Given enough time I am sure that this very clever and motivated team could have worked all this out, but with time being of the essence, reaching out to the engineering team at Bunting saved them months of trial and error.

Performance is everything with a super lightweight solar car. Energy density is key, so it was fantastic to be able to leverage some of the latest advances in Grain Boundary Diffusion magnet technology (brought back from my last trip to China) to help with this application.

With the right magnets, the right coating, and the right tooling we were set to build the two elements of the motor design.

Six weeks after the order placement, we had the magnets in stock, had completed quality inspection, and dispatched to me to take over to the Brunel Solar Team build location in Delft in The Netherlands.

The whole team was incredibly welcoming, and the engineering team was highly motivated to learn as much as they could and get their hands on building the rotating magnet assembly.

It was a privilege to work alongside these outstanding students. Future employers should be looking closely at the members of this team!

The tricky part of this build are the magnetic forces from a circular Multipole Halbach array, which are trying to twist the magnets and push other magnets away. This results in bond lines being in tension during the curing phase. This tension in the bond line is a problem and, subsequently, tooling to compress the bond line is essential. The student team ultimately designed and built this tooling with some guidance from Bunting.

The day was a complete success and both rotating magnetic assemblies were assembled without incident and within the day I spent at the facility.

As I said, ‘My Job Is Brilliant’. This was a fantastic triple win; I had a great day, the customer learned a lot, the build went to plan, and Bunting secured sponsorship on the Solar Car for 2024/2025.

A great day indeed!”

Related Articles

- Bunting and Force Engineering Design Magnetic Rollercoaster Brake

- Magnets for Revolutionary Solar Car

Magnet and Magnet Assembly Design

Bunting designs and manufactures a wide range of magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media