So much more than magnets sales ...

Bunting offer market leading technical support through a team of magnet experts, dedicated design engineers and quality professionals with full magnetic test facilities at our 2 manufacturing facilities in the UK. In addition to this we are part of the Bunting Group, with an additional 4 facilities in the USA and one in China. Our heritage goes back over 60 years, but our approach, knowledge and investment means we are a 21st Century business; ready to help you with any magnet or magnetic project, however large or small.

MAGNET EXPERTS

DESIGN CONSULTANCY

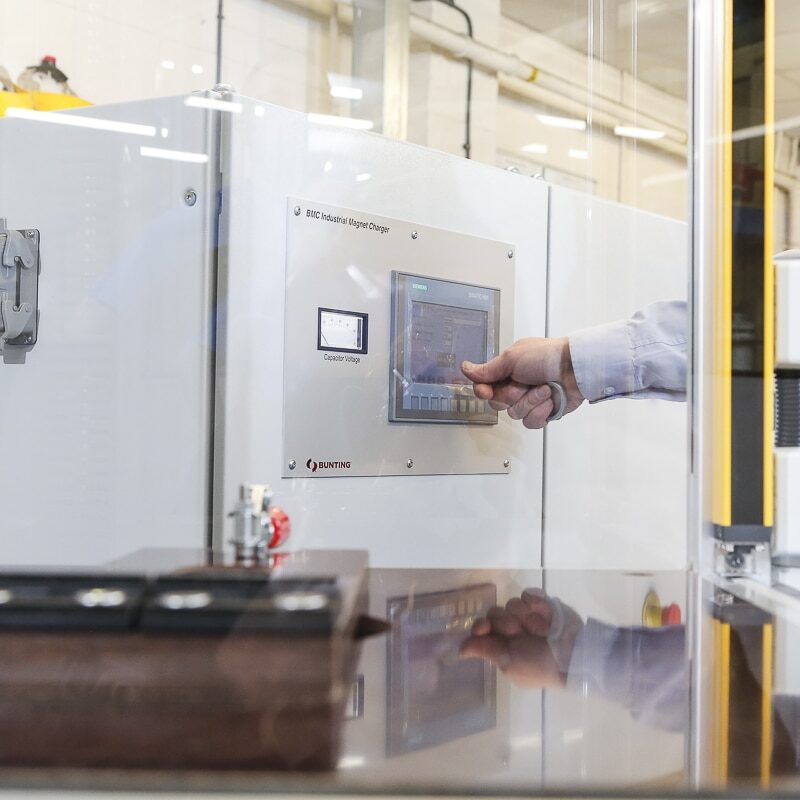

MAGNETISING & TESTING

Key elements of our Technical Departments in the UK:

- A dedicated team of 5 Design Engineers plus an Apprentice Design Engineer.

- Quality Manager whose team’s test centre has the latest magnetic test and measurement equipment, so we can guarantee all our magnets meet the specification we say they do. All material sources are regularly audited to meet the company’s quality and ethical policies.

- ISO9001 and ISO14001.

- UK Manufacturer of Precision Bonded Rare Earth Magnets.

- Manufacturing capabilities include Turning, Milling, Grinding, Sheet Metal Fabrication, MIG and TIG Welding to ISO3834, Coil winding, Electronic Assembly and Test.

- Design and Manufacture High Voltage Magnetising Systems and Fixtures, which are sold around the world to leading OEM Manufacturers and Research Centres.

Buntings key Figures in the Magnetics Industry:

Matthew Swallow

01442 875081

Matthew Swallow is our Bespoke Magnetic Assemblies Engineer/Manager. Matthew has over 15 years of experience in offering custom-engineered solutions across various industries, supported by a Masters in Aerospace Engineering. His experiences in the Aerospace, Automotive and Plastics industry gives him a wide range of successful personal projects to draw upon when helping our customers with their magnetic project. His contribution to the magnetics industry was recently recognised when he was unanimously voted to the UK Magnetics Society Committee.

Whether you are looking to produce a one-off part for a research project or improve upon an existing design, Matthew would be keen to help you with your rotating or static magnetic assembly needs.

Dr. Chris Riley

01442 875081

Dr Chris Riley is the Group Magnetics Engineer for Bunting Magnetics Europe, where he has been responsible for the company's magnet and electromagnetic design activities for over 14 years. He studied electrical engineering at the University of Sheffield, receiving his B.Eng.. M.Phil., and Ph.D. degrees under the supervision of Prof. Dave Howe and Prof. Geraint Jewell of the Machines and Drives Group. His research concentrated on the design of multipole magnetising fixtures and powder alignment systems. He continued his work for a further 2 years as a full-time Research Associate in the Machines group until 1994 when he left to join Magtec (Magnetics Systems Technology), a spin-out company from Sheffield University. There he was responsible for developing Magtec’s production magnetising equipment business. Following 8 years with Magtec, he left to join Bunting Magnetics Europe, where he has set up an in-house magnetising equipment manufacturing capability and is responsible for all technical issues relating to magnetic design, including magnetic separation, material testing, and magnetising.

Andy Hayling

01442 875081

Andy Hayling is the Technical Manager for Soft Magnetics at Bunting, having recently transferred from MagDev ltd, where he provided technical support to customers and colleagues since 2003.

Andy obtained a BEng Honours degree in Electrical and Electronic Engineering at the University of Hertfordshire, he then started his career as a power supply design engineer working in the early days of grid-connected inverters for PV systems, before moving on to specialise in power magnetics.

Andy has over 20 years of experience in diverse projects such as induction heating, and high-frequency planar magnetics, with extensive knowledge of soft ferrite core loss measurements.

Significant achievements include work done to help develop and promote an innovative high saturation power grade ferrite, and the unique FSCP product range.

David Richards

01442 875081

David Richards is our soft magnetic Technical Manager, sporting a long working history within the magnetics industry and rising through the MagDev and Bunting ranks. After receiving his B.Eng in Manufacturing Systems & Management from the University of Bath, David went on to work for MagDev as a technical Assistant testing magnetic components and assemblies, he then progressed into quality management, guiding MagDev to its first ISO-approved quality system. David then took on a more commercial role as Internal Sales Manager dealing with some major accounts within the business.

In recent years David has delved back into his roots, becoming a Technical Manager, and using his experience to help meet exact customer requirements.

Design & Testing Departments:

Our design and testing departments have world class capabilities for supporting all stages of a project from design to delivery.

From the initial computer modelling capabilities to the final magnetic test and characterisation stage we have invested heavily to ensure that the computer hardware and software we use are up to date and that the measurement equipment is calibrated to national standards and is reliable.

We combine a top of line 200 degree-rated Magnetic Hysteresis Machine, with a new National Physics Lab Calibrated Helmholtz coil and Integrate Flux Meter to establish material performance characteristics and then we couple that with rotatory and linear magnetic scanning for post-assembly validation of rotating and static magnetic assemblies.

We continually invest in magnetic assembly capabilities to ensure we can accurately deploy high-stress containment systems, either metallic (heat shrink) or carbon fibre (press fit) along with rapid production systems to produce bespoke assembly systems to control the placement of each magnet within an assembly, even if this requires a difficult Halbach array construction.

All the tooling and assembly routines are designed and carried out on-site, following a thorough contract review process. This works to ensure we are right the first time and that our lead times and on-time deliveries for brand-new projects are industry-leading.

Some of the equipment used for Design, Rapid Prototyping and Testing includes:

- 3D Printing Machines – to rapidly manufacture and develop products and tooling

- Magnetic Hysteresis Machine rated to test to 200 degrees C with National Physics Lab Calibrated Helmholtz coils and Integrating Flux Meter – for testing magnetic properties

- A range of Guass meters, Helmholtz coils and Magnetising and De-magnetising equipment.

- Opera 3D FEA Simulation Software used to design Magnetic and Electromagnetic circuits

- Co-ordinate Measuring Machine for complex dimensional measuring

- Rotary Scanners

- Vacuum Chambers

- Environmental and Salt Spray Testing

Click Here for more information on the supply of Carbon Fiber sleeves only

Contact our Technical Departments:

Magnetic Separation Sales:

sales.redditch@buntingmagnetics.com

Tel: 01527 65858

Magnetic Separation Technical Department:

redditch@buntingmagnetics.com

Tel: 01527 65858

Magnet Design:

berkhamsted@buntingmagnetics.com

Tel: 01442 875081

Technical Sales:

sales.berkhamsted@buntingmagnetics.com

Tel: 01442 875081