Carbon Fibre Containment for Magnetic Rotors

By Paul Fears | 25 March 2020

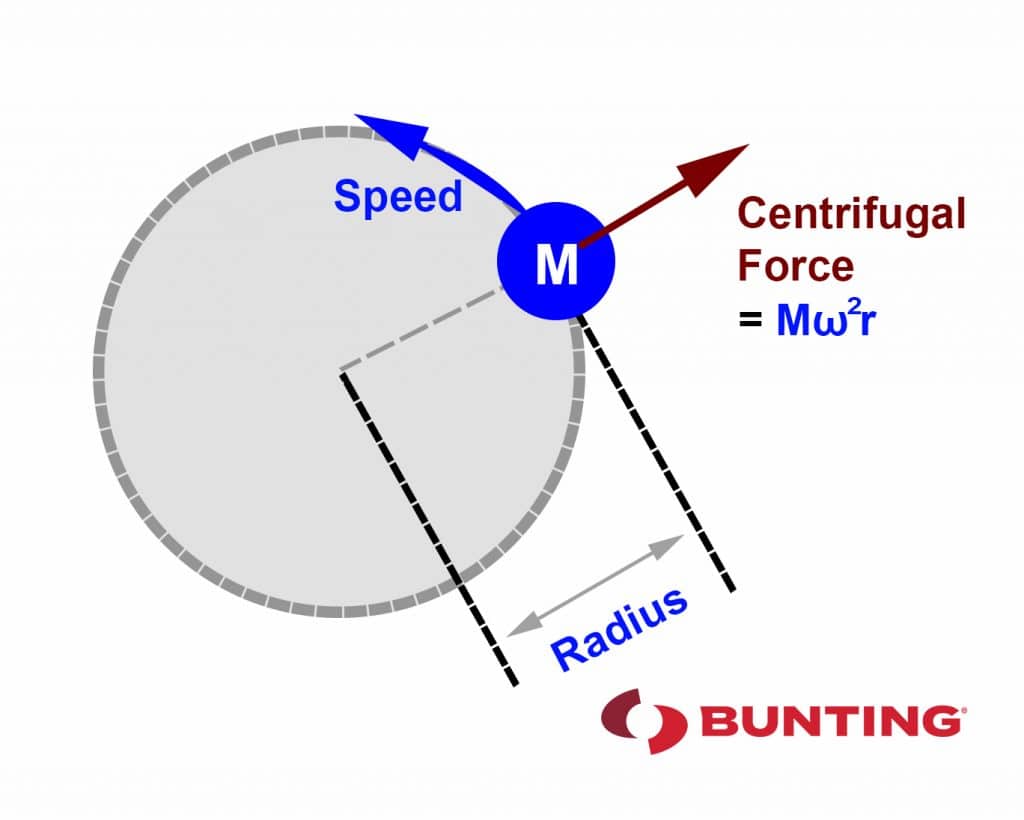

Magnetic rotors are used in a wide range of applications including motors, generators, alternators and Eddy Current Separators. These rotors spin at very high speeds and a key design consideration is ensuring that the motors do not become detached from the magnet carrier. One of the key design considerations is the resultant centrifugal force.

Centrifugal Force

Let’s start with some definitions. Centrifugal force is often confused with its counterpart, centripetal force, because they are so closely related.

Centripetal force is defined by the Merriam Webster Dictionary as, “the force that is necessary to keep an object moving in a curved path and that is directed inward toward the centre of rotation,” while centrifugal force is defined as “the apparent force that is felt by an object moving in a curved path that acts outwardly away from the centre of rotation.”

It is important to note that while centripetal force is an actual force, centrifugal force is defined as an apparent force. In other words, when twirling a mass on a string, the string exerts an inward centripetal force on the mass, while mass appears to exert an outward centrifugal force on the string.

What does this mean for magnets mounted to a rotating shaft, operating at the heart of a permanent magnet motor, generator or alternator?

When the magnets rotate they experience a centrifugal load that is proportional to the following three variables.

- The rotational speed squared;

- The mass;

- The effective diameter that the mass spins around;

To effectively hold the magnets in place during rotation, any speed containment system must look at the load that the magnets are generating and apply at least an equal and opposite force when the system is at rest.

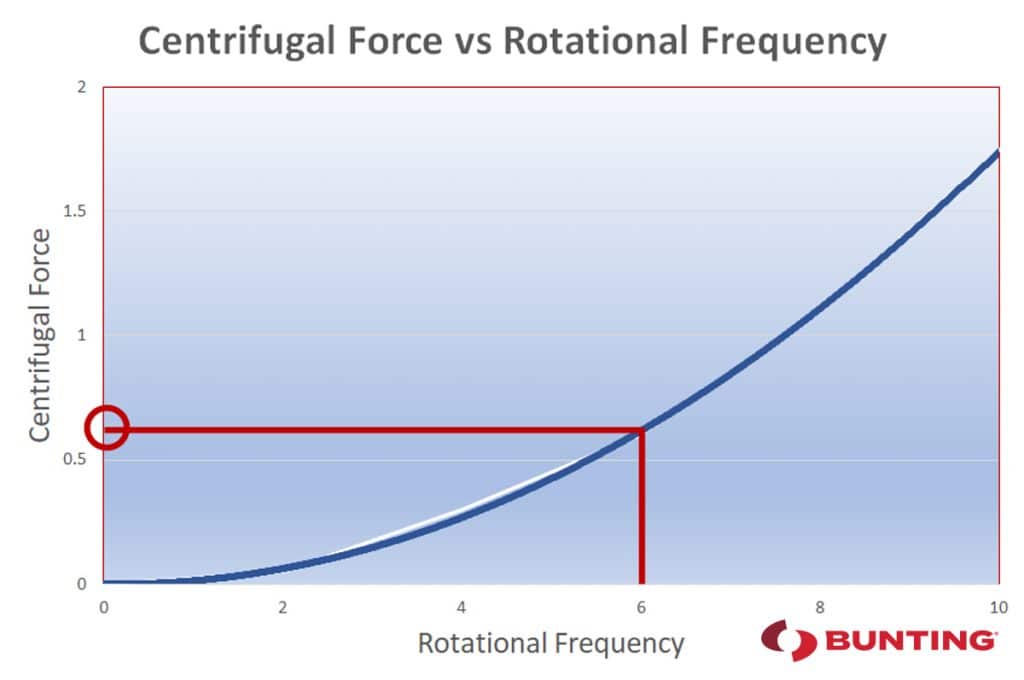

As represented in Graph 1, during the design phase consider the operating speed of the system, assess the forces to overcome, and apply that through some means of compression.

The Bunting Solutions

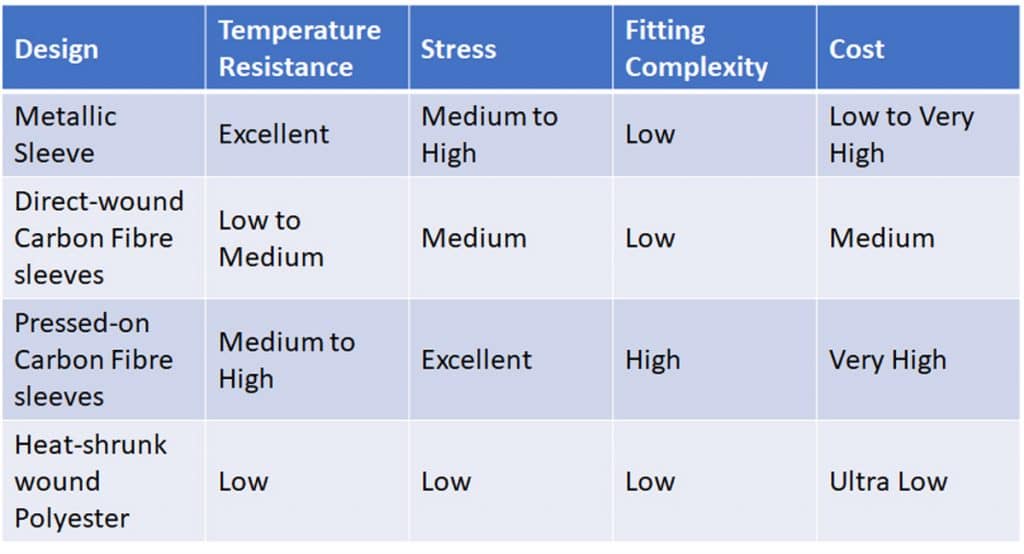

At Bunting, our engineers have been designing and building high-speed magnetic rotors for decades. Subsequently, they have experience of identifying, designing and manufacturing several engineered solutions. These include:

- Metallic sleeves;

- Direct-wound Carbon Fibre sleeves;

- Pressed-on Carbon Fibre sleeves;

- Heat-shrunk wound Polyester;

Specifications for the Different Techniques

In this review, we focus on the Carbon Fibre options with Metallic Sleeves and heat-shrunk wound Polyester reviewed separately.

Direct Wound Carbon Fibre

The maximum pre-stress possible is 450Mpa, but this is dependent on a number of criteria including the rotor diameter and temperature. The key is for the end-user of the magnet rotor assembly and the Bunting engineering team to review the design criteria and the method of containment at an early stage.

The biggest challenge to direct-wind carbon fibre is the curing temperature of the carbon fibre. The curing temperature is limited by the thermal effects of the curing process on the permanent magnets. High strength magnets may have a maximum temperature limit that is lower than the curing temperature of the carbon fibre. This could result in a permanent loss of magnetic performance. Subsequently, the carbon-fibre wrap technique may be more suited to lower strength magnets that have a higher temperature threshold.

Such a problem can be negated by using “Post Assembly Magnetisation”, a technique perfected by the Bunting engineering team. After winding the carbon-fibre onto a un-magnetised rotor, curing can take place at the perfect temperature, ensuring the right level of thermal support to the rotor with no losses, and then post-assembly magnetise the rotor in a matter of seconds. This requires careful design cooperation and some bespoke tooling (non-recurring engineering charges).

Pressed on Carbon Fibre

The maximum pre-stress possible is 1500Mpa but in practice, 1200MPa is a more realistic value.

This additional pre-stress means that other design changes are possible. This includes increasing the mass by a factor of 3 or 4. However, increasing the depth of a magnet from 10mm to 12.5mm may not substantially benefit the design or operating performance. Another option would be to increase the diameter of the magnetic rotor, but that may cause other design challenges including a larger finished component.

In our experience, increasing the running speed provides the most gains. For Permanent Magnet Motors, the optimum magnetic rotor designs are small, fast and can run hot. By using laminated magnets to reduce eddy current losses at high temperatures, a precision ground magnet surface and a pre-heat cured pressed on carbon fibre sleeve, the motor can run at very high speeds, maximising the performance envelope. At Bunting, we can also post-assembly magnetise these rotors to reduce volume production costs.

A rotor spinning at 20krpm may generate 10kw and need 75MPa of containment, but the same rotor spinning at 80krpm may generate 40kw and need 1200MPa of containment. This is only available through the fitting of a pressed on Carbon Fibre Sleeve.

The Bunting engineering team works closely with customers to identify the optimum design of pressed-on carbon-fibre sleeve, along with the necessary tooling for ease and safety of manufacture and repeatability. Bunting is able to offer an automated pressing process for high volume solutions, with an integrated vision system to measure the axial thickness of a sleeve and press exactly this distance so that the sleeves are not crushed during assembly.

The animations 1 and 2 depict one of our press tools in operation around a 50mm diameter magnet rotor, generating 1200MPa of press stress to allow an operational speed of 100krpm. Animation 1 depicts the application of the first layer of carbon fibre and animation 2 shows the final stage.

Bunting design and manufacture a wide range of magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on Carbon Fibre wrapping of magnetic rotors, bespoke magnet assemblies or magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: Sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology