Magnetising Fixture Winding for Magnet Ring Sensor Project

By Paul Fears | 01 November 2021

Bunting’s engineering team work with companies on many magnet product designs, from concept through to manufacture. This project focused on the feasibility of designing, manufacturing, and supplying a permanent magnet ring to produce a sinusoidally varying flux density waveform for a sensor application. A sine wave or sinusoid is a mathematical curve that describes a smooth periodic oscillation and forms a continuous wave.

Project Plan

On a project which involves feasibility through to manufacture, there are four key stages:

- Modelling – finite element modelling of the magnet geometry enabled engineers to assess the feasibility of producing a sinusoidal varying flux density waveform;

- Magnet material – review all available magnet materials capable of obtain the required flux density waveform of the correct magnitude;

- Magnetisation – consider optimum method of magnetising the magnet ring with specific focus on the magnetising fixture design;

- Operating parameters – assess potential mechanical issues related to the high rotation speed and high temperatures;

Magnet Ring Modelling

The 2D finite element magnetic ring modelling determined the optimum magnet size and fixture design to produce a flux density waveform with the lowest total harmonic distortion as close as possible to the magnet surface. Over 750 tests provided the necessary data to conclude that for an isotropic ring magnet, through careful design of the multipole magnetising fixture, it is possible to design a magnet to produce a sinusoidal varying flux density waveform, within the available space envelope, at a distance of 1mm above the magnet surface.

Magnet Material

Modelling identified two magnet materials to meet the peak flux density of the sensor:

Magnetisation

The magnet type governs the method of magnetisation. The energy required to magnetiser the bonded neodymium magnet was 7 times greater than the ferrite, which would affect the design of the magnetiser and control system.

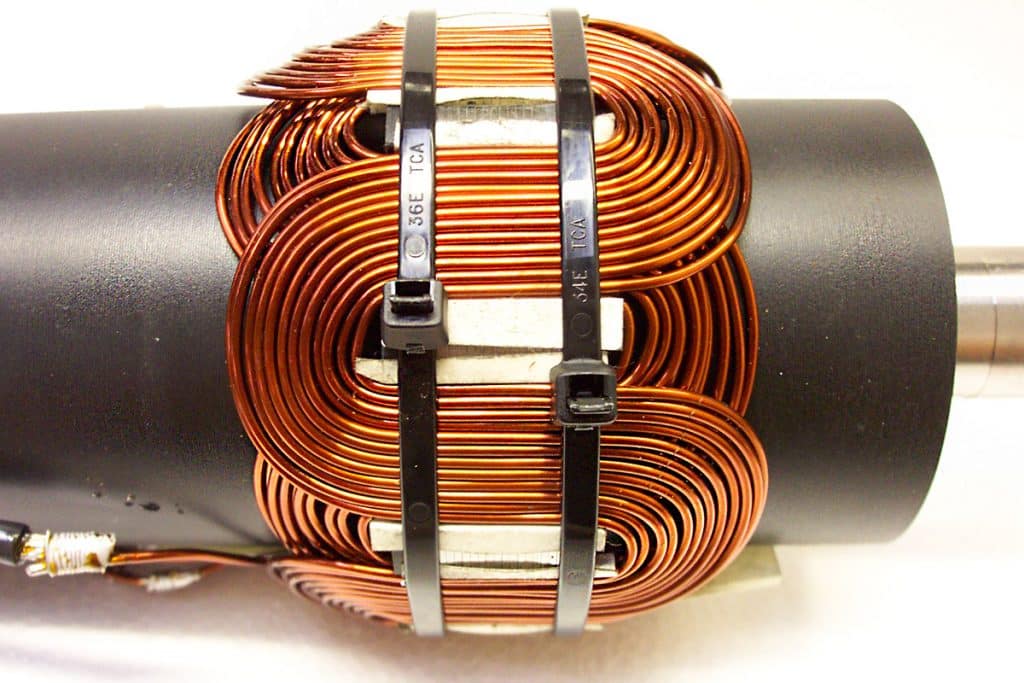

The magnetising fixture including a winding with a large number of distributed turns to achieve a true sinusoidal waveform with a very low harmonic distortion.

Mechanical Stresses

The bonded neodymium and ceramic ferrite magnets have very different mechanical attributes. The design team considered the physical integrity and magnetic performance of both materials when operating at high rotation speeds (approx. 8000 rpm) and in higher temperature environments (up to 120°C).

Conclusion

The project team concluded that isotropic ferrite magnet ring would produce a sinusoidal flux density waveform of the correct magnitude and within the specified limits of total harmonic distortion.

Additionally, the ferrite magnet ring was less than 10% of the cost of the neodymium ring. This resulted in the recovery of the total cost of the design work in magnet material savings within a single year. This project highlighted the financial and performance advantages of assessing magnet design at an early stage.

Further research was required prior to finalising the design.

Related Technical Articles

Magnet and Magnet Assembly Design

Bunting designs, manufactures and supplies a wide range of magnets, magnet setters, magnetisers, and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media