Neodymium Magnets – Frequently Asked Questions

By Paul Fears | 15 September 2020

Neodymium Iron Boron Rare Earth are the strongest permanent magnets presently available. They are a hidden key component of mobile phones, cars, and computers. When speaking to customers, we identified a number of frequently asked questions, which we will attempt to answer in this latest blog.

- Technical product information: Neodymium Magnets

What are Rare Earth Magnets and why?

Rare Earth Magnets are powerful permanent magnets composed of rare earth elements (REE). Rare earth elements are a set of seventeen chemical elements in the periodic table making up the lanthanide series of metallic chemical elements, as well as scandium and yttrium. Neodymium (used for Neodymium Iron Boron magnets) and Samarium (used for Samarium Cobalt magnets) are both rare earth elements and, hence, their associated magnets are referred to as “rare earth magnets.” Note that “Rare” relates to the properties of these materials, not their scarcity in the Earth’s Crust.

How do you make Neodymium Magnets?

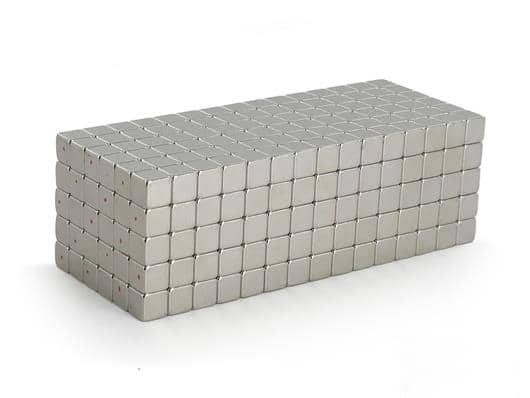

Neodymium Magnets are made from an alloy of neodymium, iron, and boron. The constituent elements are blended together and then ground very finely under a non reactive environment. Once the powder is in the right blend and at the right domain size, the powder is pressed under high pressure and a magnetic field to create a “Green Magnet Block”. Using classic powder metallurgy techniques this anisotropic material is sintered and heat-treated over a period of weeks, then rapidly cooled to lock in the final metallurgical state and the magnetic orientation. Typically, Neodymium Magnets have a protective coating added to them, such as nickel or copper nickel plating to prevent corrosion and damage.

- Technical product information: Plastic Bonded Neodymium Magnets – Bremag

What is the difference between N35, N42, N50 and N52 Neodymium Magnets?

Neodymium Magnets are available in different grades defined by the notation N35 etc. The “N” stands for neodymium, with the number referring to its grade. The grade relates to the maximum energy product of a magnet measured in Mega-Gauss Oersted (MGOe). For example, an N42 Neodymium Magnet has a maximum energy product of 42 MGOe. As a general rule, the higher the grade, the stronger the magnet. Consider the energy product of a magnet as being equivalent to MAh (milli-ampere hours) of a battery. Different brands of AA batteries have different power ratings and capabilities, but all have the same form factor. In the same way, a magnet of one given size can have many different energy densities and performance characteristics.

- Technical product information: Neodymium Magnet Grades

Are Neodymium Magnets durable?

Once produced, and without a coating, Neodymium Magnets are vulnerable to corrosion such as rusting. This is because the metallurgical structure of the material is Hydroscopic (meaning it can absorb water) and as the structure is 14 parts of 17 Iron, this reacts preferentially with water to form rust; literally rotting form the inside out. However, once coated the Neodymium Magnets have a long life expectancy. There are a wide range of coatings to suit different environments.

Samarium Cobalt magnets are best suited for use in corrosive environments as there is barely any free iron in the matrix , although the magnetic intensity may be less.

Un-magnetised Neodymium Magnets are reasonably strong. However, once magnetised every magnetic domain is trying to break free from its neighbour. This means that a small shock, such as two magnets colliding, or a magnet colliding with a piece of magnetic steel, or a knock with any hard object, can cause the microstructure to rupture catastrophically, leading to chips and breaks. This makes magnetised Neodymium a very brittle material, but this is a function of both the inherent metallurgy and the fact they are magnets. If two Neodymium Magnets attract together, they continually accelerate in speed as they draw together and the resultant intense shock force will cause the brittle magnets to chip or shatter.

Protective coatings can reduce the risk of damage, but working to recommended handling techniques can prevent such damage.

Are Neodymium Magnets dangerous?

Neodymium Magnets are extremely powerful and when handled correctly are perfectly safe. However, there are strict health and safety considerations needed during handling including:

Pacemakers and medical devices

People using a pacemaker or any other medical device adversely affected by magnetic fields should not handle Neodymium Magnets. Although the depth of magnetic field is commonly shallow, the magnetic power may interfere with the medical device. This is a severe health and safety risk.

Eye Protection

As there is a risk of Neodymium Magnets chipping or shattering during handling, safety glasses should be worn.

Handling Injuries

The force and speed in which Neodymium Magnets attract to each and to steel (surfaces and tools) is significant. Handlers should also wear suitable safety gloves and ensure that the Neodymium Magnets are kept a safe distance away from each other and any magnetically-susceptible surface or tool.

Neodymium Magnets are not toys

Neodymium Magnets are not toys and children should not be allowed to handle neodymium magnets.

- Detailed information on Health and Safety Advice for Magnets

Any Other Questions?

The listed questions are a very small selection of those we are asked each day. Thankfully, we have a engineering team with many years of magnet experience who are available to help. To ask a specific question or for further information on Neodymium Rare Earth Magnets, please contact us via:

Phone: +44 (0)1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology