Offshore Winch Eddy Current Brake with Magnetic Powers

By Paul Fears | 13 January 2017

Bunting’s magnet product design team were contacted and asked to manufacture a Magnet Assembly that would act as an emergency eddy current brake on an offshore winch.

The original design called up bespoke Neodymium Rare Earth Magnets with a strength of 50MGOe (MegaGauss oersted). Such an assembly had an ten-week lead time, which was too long for the customer.

The Eddy Current Brake Design Process

The design teams of Bunting and the customer worked together on a new magnet configuration. The magnet shape in their original design was modified to accommodate a standard magnet Bunting held in stock. The selected neodymium rare earth magnets are commonly used in the manufacture of large Plate Magnets which are used to separate ferrous metal contamination from free-flowing materials.

However, the new magnet configuration meant that there was a slight reduction in magnetic energy. In order to produce a similar performance, a thicker magnet block was used. This produced the necessary magnetic force.

The final design reduced the lead time from 10 to 2 weeks. In addition, the design lowered the total cost of the magnet assembly.

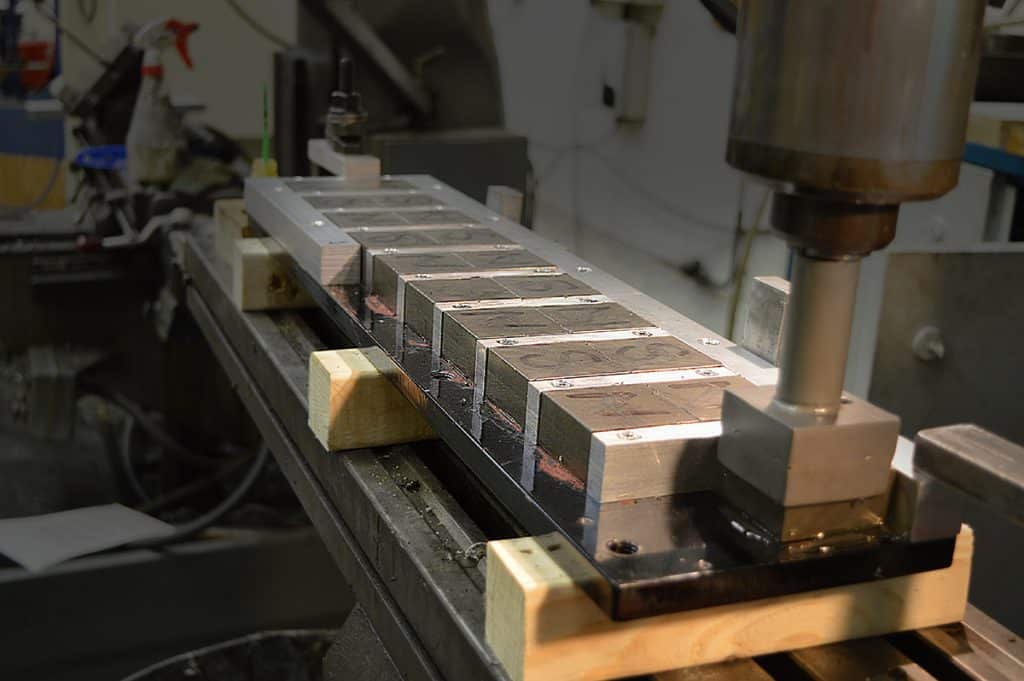

The Final Magnet Assembly Design

The magnet array design features a 10-pole alternating pattern that is mirrored across the aluminium disk. The alternating polarity allows the re-circulation of magnetic field in the back iron plate. The back iron plate is sized to fully saturate magnetically, thus preventing stray leakage from the rear of the assembly. The magnetic field projected from the exposed side is designed to link up with the opposite structure. This creates a region of high intensity magnetic field that interacts with the moving aluminium to generate the braking eddy currents. An ‘Eddy Current’ is a localized electric current induced in a conductor by a varying magnetic field.

The finished Magnetic Assembly is commonly know as an ‘Eddy Current Brake‘, similar to the technology used to safely stop roller coasters. This is a passive, fail safe technology that slows in proportion to the differential in speed of the static magnet assembly and the rotating aluminium part.

Related Technical Article

Magnet and Magnet Assembly Design

Bunting designs and manufactures a wide range of magnet setters, magnetisers, magnetising fixtures, magnets and magnetic assemblies. Many are bespoke for specific applications. For further information, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media