Surface Mounted Arc Magnets

By Paul Fears | 13 May 2020

Bunting is capable of supplying almost any shape and size of a permanent magnet, but one of the most popular shapes is the arc. Arc magnets are used in a wide range of magnet assemblies, but in particular, surface mounted electric machines.

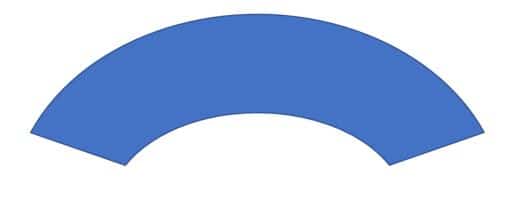

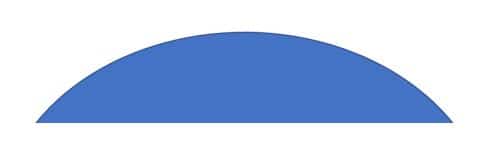

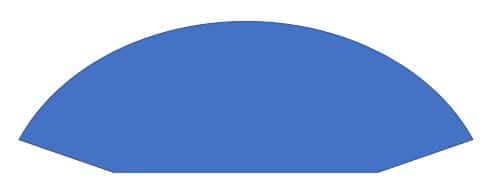

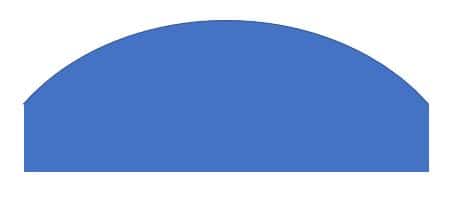

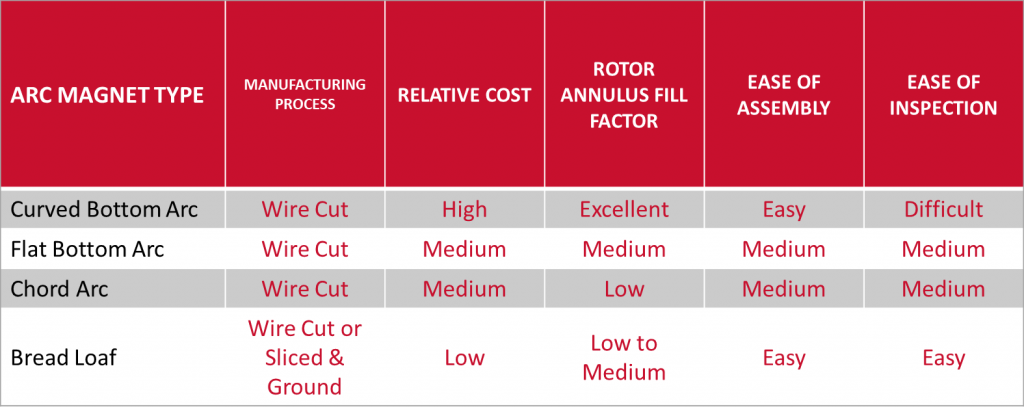

There are four main types of arc magnets and these are:

Each arc-type has advantages and disadvantages when considering the impact on electric machine design. Priority is given to selecting the optimum arc design rather than the production costs as the shape is fundamental to the performance. The cost of the magnet materials are far higher than the production costs, and the magnet profile only becomes an issue when producing very high volumes.

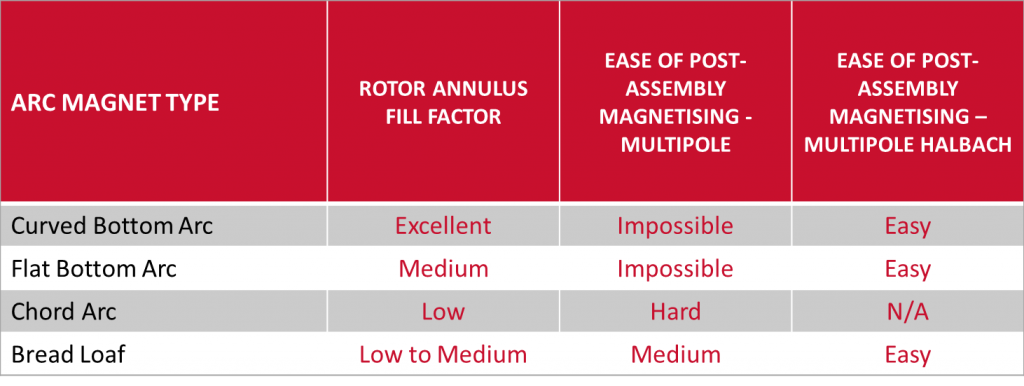

A simple guide to some of the arc characteristics can be seen in the table below;

Assembly

During the design stage, the focus is on the magnetic performance of the permanent magnet rotor. Once the optimum magnetic design is confirmed, the design team work alongside production to consider the assembly (i.e. the process in which the magnets are secured to the shaft). There are then two options for the assembly:

- Assemble using Charged Magnets: There are inherent difficulties using charged magnets as they are incredibly brittle and the high magnetic strength poses serious safety concerns;

- Following the introduction of new production techniques, Bunting provides a post-assembly magnetising solution;

Assembly Using Charged Magnets

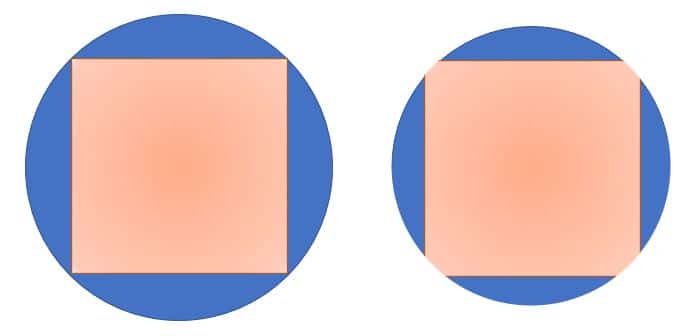

A flat bottom magnet, touching down onto a flat surface, is the most controlled and lowest risk option for magnetised magnet build. However, this requires a more expensive and complex faceted shaft onto which to mount the magnet. In contrast, when using a simple magnet arc, with round internal diameter (ID) matching to a plain shaft outer diameter (OD), the machining costs of that shaft are lower.

In addition, for ease of assembly, a faceted shaft may have a small recess into which to mount the magnet. This increases production costs but ensures the magnet does not hang over a faceted surface, which would prevent the next magnet along to fitting into the correct position.

Post Assembly Operations

Producing a tight concentricity tolerance or final OD tolerance for arc magnet profiles add an additional layer of assembly complexity.

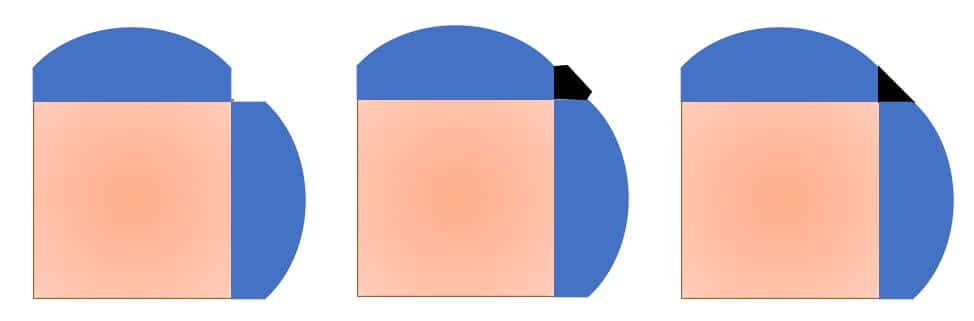

- A ‘Curved Bottom’ arc magnet needs no more processing and is immediately ready for grinding

- A ‘Flat Bottom’ arc magnet needs no more processing and again is ready for grinding

- A ‘Chord’ arc magnet will present a challenge for grinding. If the magnet moves across the whole width of a 4-plus faceted shaft, then as the rotor is ground the shaft starts to be exposed and the grinding operation is now over two dissimilar metals

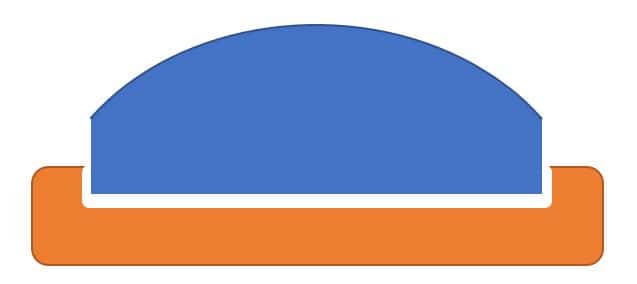

- A ‘Bread Loaf’ arc magnet presents the greatest manufacturing challenge. Once mounted on the shaft, the edges of the arc magnet are exposed and there is no longer a smooth transition around the OD of the rotor. As magnets are incredibly brittle and damage very easily, the gap created by the magnet arc choice must be filled with a reasonably hard but easily worked material. This material fills the void before being ground back, whilst staying in position when rotating.

Magnet Containment

For any sort of circumferential containment (such as when using carbon fibre), similar manufacturing considerations apply. It is imperative that the magnet rotor has a smooth round surface prior to applying the wrap, whether carbon fibre (wrapped or pressed) or a heat-shrunk metallic tube.

Magnetising

With the aim of simplifying the manufacturing process and improving safety, Bunting’s technical engineering team has developed technology for post-assembly magnetisation. Subsequently, a complex magnet assembly is constructed unmagnetized and then charged.

There are many advantages to post-assembly magnetisation. Constructing the magnet assembly is easier and the time is taken shorter. There is also a reduced risk of mistakes occurring during assembly (e.g. incorrect polarity orientation). Post-magnetisation means that the polarity and magnetic field are exactly as required for every magnetic component. The benefits of post-assembly magnetisation are discussed in the technical article ‘Post Assembly Magnetisation for the Automotive Sector‘.

However, it is not possible to post-assembly magnetise a magnet rotor comprising of ‘Curved Bottom’ and ‘Flat Bottom’ arc magnets. This is because it is impossible to fully magnetically saturate ‘Curved Bottom’ and ‘Flat Bottom’ arc magnets.

When there is a small air gap between ‘Chord’ arc magnets and ‘Bread Loaf’ arc magnets, then post-assembly magnetisation is possible. However, when a transition magnet is introduced, and a Surface Mount Halbach rotor is created, then magnetising is not just possible, but also greatly simplified.

Related Technical Articles

Bunting design and manufacture a wide range of magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on bespoke magnet assemblies or magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology