Magnet, Magnet Assembly and Magnetiser Manufacturers

Bunting-Berkhamsted specialises in the design and manufacture of Magnets, Magnet Assemblies, and Magnetisers. Located in Berkhamsted in the United Kingdom, Bunting-Berkhamsted is part of the Bunting Group, one of the world’s leading suppliers for over 60 years with manufacturing plants located worldwide. Bunting-Berkhamsted is unique as a designer and supplier of both Magnets and Magnet Assemblies as well as Magnetisers.

Magnet Manufacturer

Bunting-Berkhamsted design, manufacture and supply a diverse and extensive range of magnets and is one of the leading European providers. The magnet range includes Neodymium, Samarium Cobalt, Ferrite, Alnico and Plastic Bonded Neodymium Magnets (Bremag). Standard magnets are sold online via Bunting-eMagnets, the first online magnet store in the UK. Plastic bonded magnet technology (Bremag) enables the design and manufacture of bespoke shapes and designs of Neodymium magnets for specialist applications in many engineering sectors.

Magnet Assemblies

The Bunting engineering team includes engineers with decades of experience in magnets and magnetics. With this engineering expertise, Bunting designs and manufactures bespoke magnet assemblies for companies in many industries including the automotive and aerospace sectors. The size of a typical magnet assembly ranges from a few millimetres in length upwards, with the many bespoke designs tailored to suit specific sizes and magnetic strengths.

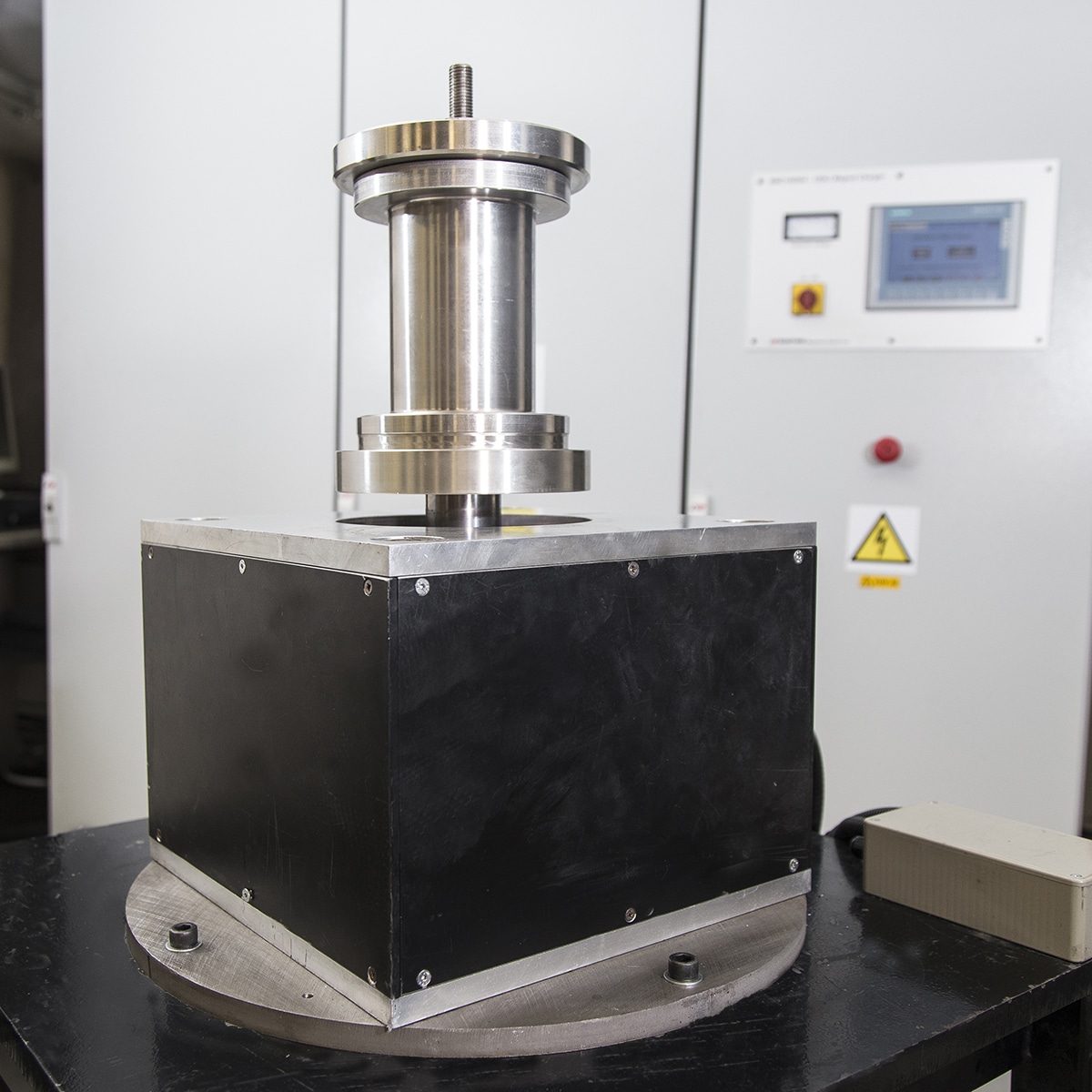

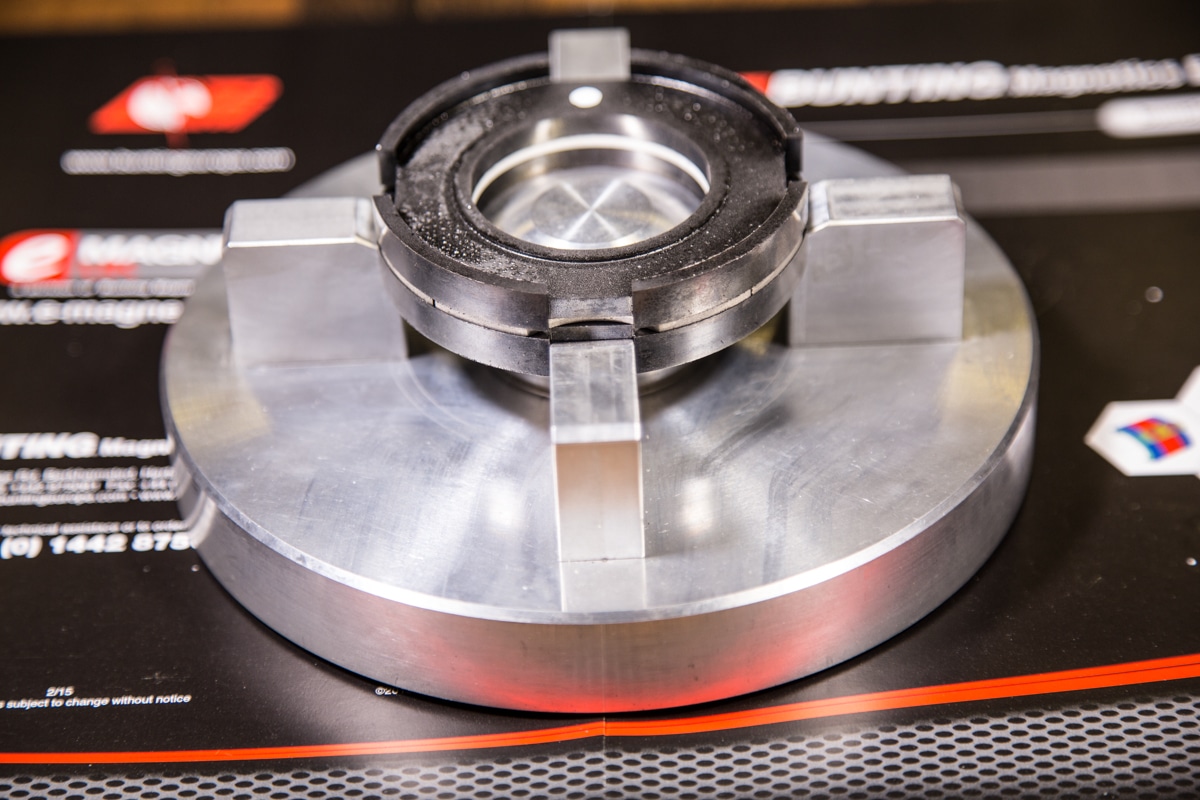

Magnetisers

Bunting-Berkhamsted offers one of the most comprehensive ranges of magnetisers in the world. The range includes Industrial Magnetisers, Bench-top and Laboratory Magnetisers, as well as Magnet Setters and Magnetising Fixtures. This magnetising equipment is commonly purpose designed and built for specific applications. The Bunting team design and build the magnetiser, the magnetiser control panel, and the magnetising fixture. These are then extensively tested at the Berkhamsted plant. Magnetisers are used widely in the electronics, automotive and aerospace sectors.

Future Magnet Development

The Bunting engineering team is continuously assessing advances in magnet technology to introduce new and better performing magnetic materials into the market. Presently, the company is a valuable member of the EU-funded SUSMAGPO project which is working on methods to recover, reuse and recycling rare earth magnets used in electronics, vehicles and other technology.

Bunting-Berkhamsted is accredited with ISO45001 (health and safety management), ISO9001 (quality management) and ISO14001 (environmental management).

Bunting is widely regarded as a great example of British engineering and manufacturing excellence, exporting quality and well-designed equipment worldwide