Sensor Magnets

By Paul Fears | 23 July 2020

Sensors are used everywhere from vehicle engine management systems to Smartphones determining if the flip cover accessory is closed. Modern everyday life would be very different without sensors and the operation of many of these sensors rely on magnetism. As products evolve, so have the range and specification of sensor magnets.

A magnetic sensor converts magnetic or magnetically encoded information into electrical signals for processing by electronic circuits. The device is able to identify position, velocity or directional movement.

Any magnetic sensor works on the basis of one of two principles:

- The Hall Effect;

- The Reed Switch

The sensor application determines the optimum design of sensor and the type and design of magnet or magnet assembly.

- Technical information on Sensor Magnets

Hall Effect Sensor

Hall Effect Sensors are used for proximity sensing, positioning, speed detection and current sensing applications. This type of sensor measures the magnitude of a magnetic field. Hall Effect Sensors are activated by an external magnetic field whereby, when the magnetic flux density around a sensor exceeds a pre-set limit, it is detected by a sensor. This then generates an output voltage called the Hall Voltage. This effect was discovered by Edwin Hall in 1879.

Sensors using the Hall Effect are very robust and immune to dust, mud and water and are reliable in extreme environments. Such characteristics are well-suited to positional sensing applications in preference to optical or electro-mechanical designs.

Sensors designed around the Hall Effect include:

- Position and motion sensing, as in brushless DC motors;

- Automotive ignition and fuel injection

- Wheel rotation sensing

- Electric motor control

- Industrial applications such as joysticks to control hydraulic valves in plant such as mining trucks, loaders, cranes, etc

Reed Switch Sensor

The switching mechanism of a Reed Switch comprises of two ferromagnetic blades, separated by only a few microns. When a magnet approaches these blades, the two blades attract toward one another. Once touching, the blades close the normally open (NO) contacts, allowing electricity to flow. Some reed switches also contain a non-ferromagnetic contact, which forms a normally closed (NC) output. An approaching magnet will disconnect the contact and pull away from the switching contact.

The Reed Switch dates back to 1936 when it was invented by Walter B. Ellwood at the Bell Telephone Laboratories in the USA.

Reed switches are incredibly reliability for a mechanical switch and able to function for billions of cycles before failing. Additionally, with the sealed construction, such switches are suitable for use in explosive environments.

Sensors using the Reed Switch technology include:

- Door and window sensors in burglar alarms;

- Speed sensors on bicycles;

Magnet Types

ALNICO is a popular choice of magnet material for sensors due to the excellent resistance to heat (up to 500° C) and corrosion. Samarium Cobalt is another option due to their high magnetic performance, especially at temperatures between 150 and 180°C. Another popular alternative is BREMAG, a plastic-bonded magnet neodymium (NdFeB) material.

- Technical information on ALNICO Magnets

Sensor Magnets Design

Bunting design engineers work closely with sensor manufactures as well as the end-users in the automotive and white-goods industries to optimise the magnet or magnet assembly design for any given sensor. This includes developing bespoke magnet setters and magnetising fixtures to maximise the magnetic properties.

Magnet Setters

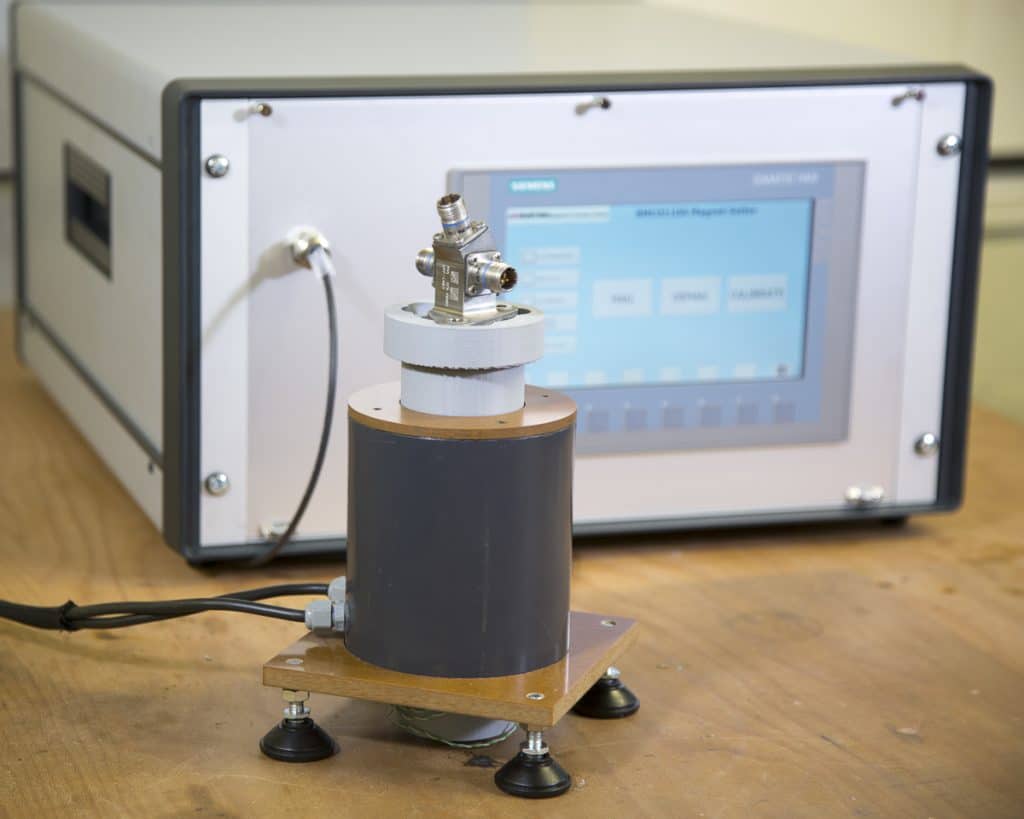

The Bunting BMCS range of magnet setters are used for magnetising and setting permanent magnets. The magnet setters utilise capacitor discharge technology to initially generate a positive magnetising field and then a decaying oscillating wave form de-magnetising pulse inside the fixture bore.

As can be seen in the video of an automated magnet setter, the magnet is embedded in a rotor shaft and is positioned relative to an inbuilt magnetic field sensor.

- Technical information on Magnet Setters

The unit is zeroed, a field value goal is specified on the control screen and then the calibrate button is pressed. In the “Calibrate” mode, the machine will deliver a saturating charge to the magnet inside the magnetising fixture, then the polarity of the magnetising field is automatically reversed and the level of demagnetisation is gently increased until the Gauss meter feedback reports that the set value has been achieved.

This is shown in the video as the voltage in the bar on the far right initially pulses at full capacity and then pulses in the de-mag mode at a much lower rating. Once the desired value is achieved within the tolerances specified the setter stops and the magnet can be removed.

ALNICO (AlNiCo) magnets are best used in this environment as they have a non-linear B-H curve (the curve characteristic of the magnetic properties of a material or element or alloy). This magnet material can demagnetise in free space and is therefore often protected by magnetising already inside a magnetic circuit. For sensor magnets made from ALNICO, all of the variability of material properties, production tolerances, mechanical tolerances, etc are negated by taking a fully saturated magnet and then demagnetising back gradually until a desired value is achieved. This ensures that when in operation the magnet in the sensor will continuously function within specification.

This type of ‘magnet setting’ is only available as standard with ALNICO magnets, although development work is on-going to provide a similar service for Samarium Cobalt (SmCo) magnets and magnetic assemblies, utilising a different coercivity mechanism, whilst yielding similar results.

Bunting design and manufacture a wide range of magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on bespoke magnet assemblies and magnet designs for sensor of other applications, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology