Magnetiser and Magnet Setter Export Success

By Paul Fears | 22 June 2021

Successful implementation of an overseas business development strategy has resulted in orders from Italy for a bespoke Industrial Magnetiser, complete with control cabinet, and a Magnet Setter. Bunting’s UK engineering design team will design, build and test the magnetisers, control and magnet setter.

Industrial Magnetisers and Magnet Setters enable the charging of both permanent magnets and magnet assemblies, with a diverse range of applications in the electronics industry. The two customers in Italy purchased a model BMC 10050 and a BMCS1510 magnet setter respectively.

BMC Industrial Magnetisers

The BMC Series of Industrial Magnetisers meet the higher energy demands of the some of the more complex industrial applications. The modular construction enables the supply of BMC Magnetisers to suit a wide range of energy levels, with different voltage and capacitance configurations depending on the application, as well as multiple magnetising fixture outputs. The Magnetiser is PLC controlled and interfaces with a customer’s own production systems. These Magnetisers suit most industrial applications, from simple two-pole fixtures to high-energy multi-pole magnetisation such as flywheels, permanent magnet rotors or traction motors.

The Bunting engineering team provides continual support for all magnetisers, with 24/7 remote monitoring, providing customers with an unrivaled level of customer service.

- Technical Product Information: BMC Series Industrial Magnetisers

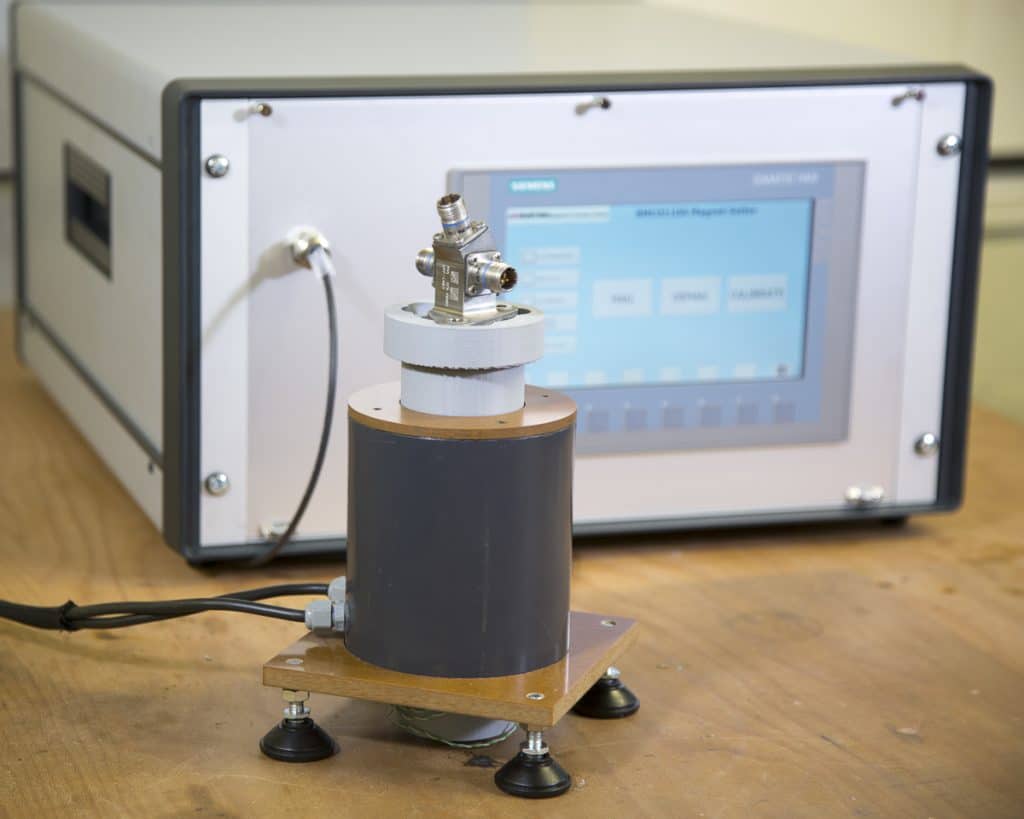

BMCS Magnet Setters

The BMCS1510 model is part of the range of magnet setters used for magnetising and setting permanent magnets. The magnet setters utilise capacitor discharge technology to generate either a pulsed magnetising or demagnetising field inside the fixture bore.

In the “Mag” mode, the machine will deliver the full charge to the magnetising fixture, while in the “Demag” mode, the polarity of the magnetising field is automatically reversed and level of demagnetisation controlled by the dial on the control panel.

Used in conjunction with a suitable magnet measurement system, these magnet setters are used to calibrate a magnet to specific working point.

- Technical Product Information: BMCS Magnet Setter

Business Development in Italy

The Magnetiser orders from Italy follow the implementation of a campaign to develop European markets. In 2019, Bunting appointed Stefano Maiaroli to head up business development in Italy and Southern Europe. The launch of an Italian language website followed, which proved to be the source of both Magnetiser orders.

The two companies purchasing the Industrial Magnetisers come from the electronics sector, with one company manufacturing audio equipment and the other specializing in switchgear and relays. The projected shipment dates are August and September 2021.

“Bunting is a leading global designer and manufacturer of industrial magnetisers,” explained Stefano Maiaroli, “and we’ve worked hard increase awareness of our capabilities in Italy and Southern Europe. Both orders originated as enquiries on our website, highlighting the importance of having technical information easily available in someone’s native tongue.”

Related Articles

Magnet and Magnet Assembly Design

Bunting designs and manufactures a wide range of magnet setters, magnetisers, magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media