AlNiCo Magnet Setter Development

By Paul Fears | 29 March 2021

Bunting engineers have developed a new Magnet Setter for AlNiCo magnets.

AlNiCo Magnet Properties

AlNiCo’s relatively low coercive force (Hc) means that the magnet material is easily magnetised to saturation, as well as fully or partially demagnetized by external fields. This makes an AlNiCo magnet easy to magnetise when part of an assembly, but could also lead to self demagnetisation if the overall circuit design is poor. For example, removing an AlNiCo magnet from a motor assembly puts the magnet in an open circuit condition and will cause self demagnetisation (the working point is taken beyond the ‘knee’ of the Intrinsic curve).

- Technical Product Details: AlNiCo Magnets

Self demagnetisation occurs because the magnetic field from the magnet can pass back through the magnet itself (the magnetic path is more preferable than the air surrounding the magnet), which is thus an external demagnetising field applied by the magnet to itself (all magnets in free space will apply a self –demagnetising field, but only magnets with very low working point and/or a low intrinsic coercivity (Hci) values will show demagnetisation).

A major advantage of this sensitivity to external magnetic fields is that AlNiCo is easy to “tune”. In applications such as spectrometers, test equipment and sensors, the material being investigated gives uniquely identifiable results, but only if the magnetic field being applied is within a precise range.

This is where the low Hci of AlNiCo is extremely useful. It is possible to build a magnetic assembly using AlNiCo, magnetise it to full saturation (with a pulse of sufficient strength of up to 1 Tesla and longevity to overcome any eddy currents in magnetic steel components), then deliberately weaken it magnetically.

This reverse field pulse is a decaying negative oscillating wave form that sets the magnet within the assembly to the required field strength at the desired location. This method of tuning is sometimes also known as “knocking-back” or “setting”.

In such cases, magnet assemblies should always be fully magnetised and then weakened, rather than just only weakly magnetised. This is because “knocking back” demagnetises the zones (domains) of the magnet that have the worst Hci values. This leaves the domains that are harder to demagnetise, which results in a more stable magnet, which is better at resisting being demagnetised accidentally (which is the reason for “knocking back” also being known as “stabilizing”). Some designs will deliberately request a stabilization to provide a designed-in lower magnet performance, but with an improved resistance to demagnetisation by external magnetic fields.

The AlNiCo Magnet Setter

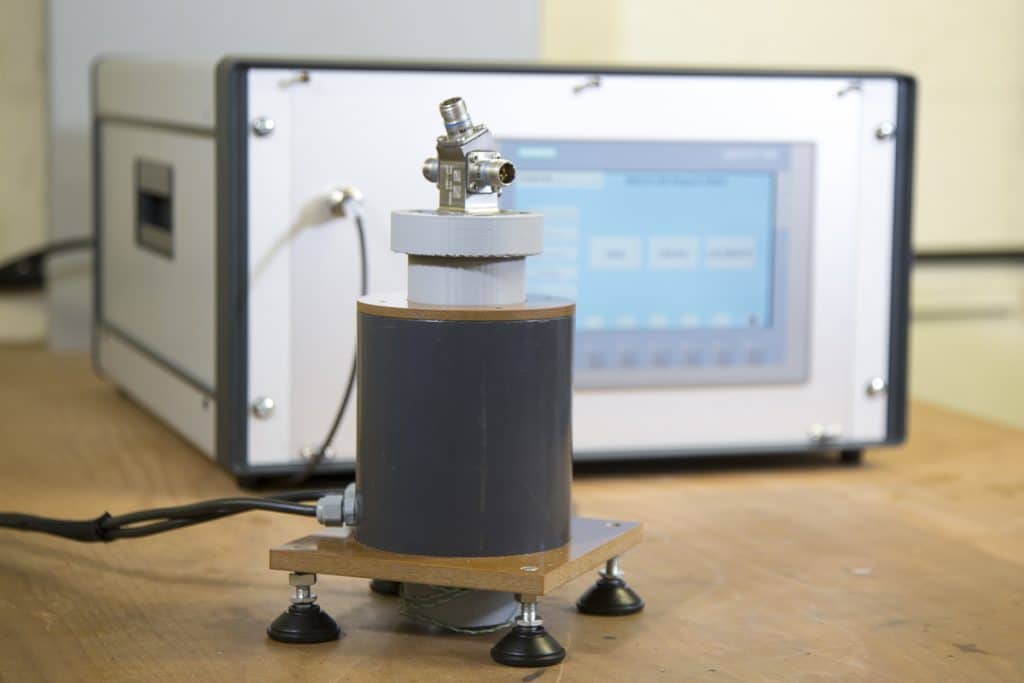

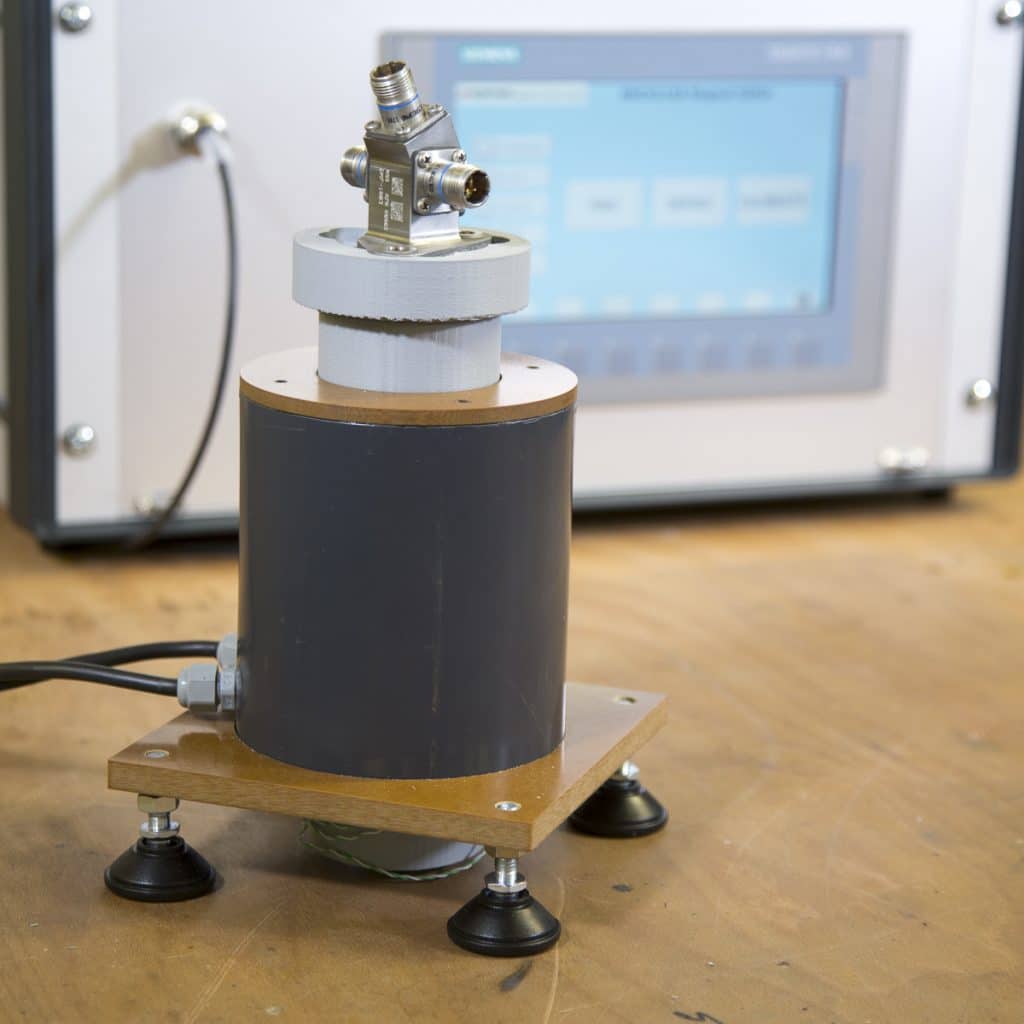

In order to meet the demands of the sensor and motor industry, Bunting has developed an AlNiCo Magnet Setter. The new magnet setter is capable of fully magnetising an AlNiCo magnet within a magnet assembly and then automatically knocking it back to the required value, all in one process. Using the integrated Gauss meter and the simple HMI interface, the target Gauss value is entered into the control mechanism. A magnet assembly is inserted into the bespoke coil, before the process is initiated by pressing the start button. Once the process is complete, the unit goes green and the assembly can be removed.

- Technical Product Details: Magnet Setters

Depending on the sensitivity, the voltage change per fire can be increased in one volt increments, allowing a Gauss change from 1 Gauss per fire.

The decaying oscillating wave form allows for the unit to set to BSI standards and provides the most reliable long term magnet performance.

While the units themselves are generic they are customised to suit the end application by designing the coil around the magnet assembly and the magnet location within it. The number of feedback gauss meters are also variable depending on the number of measurements required.

Related Technical Article

Magnet and Magnet Assembly Design

Bunting designs and manufactures a wide range of magnet setters, magnetisers, magnets and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media