Stray Magnetic Fields and Safety

By Paul Fears | 12 September 2022

Bunting is at the heart of the electrification program of the world’s vehicles. By producing magnetising systems that allow for genuinely error-free assembly and providing 100% inline testing, Bunting supports automotive and aerospace programmes looking to create new modes of travel and improve efficiency. Bunting is proud to support this sustainable engineering activity to provide a greater level of energy security for all future generations.

During the development of these electric machine magnetising systems, one of the most common questions our customers ask our engineers is: “How can we keep our staff safe from stray electromagnetic fields?”.

Stray Magnetic Field Legal Responsibilities

On June 29th, 2013, the European Commission repealed Directive 2004/40/EC and published Directive 2013/35/EU on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (electromagnetic fields) (20th individual Directive within the meaning of Article 13(1) of Directive 89/391/EEC). The 21-page document is a major directive designed to protect workers across a wide spectrum of different fields. However, trying to extract the exact area of the directive that applies to Bunting’s magnetic and magnetising products is challenging.

As a responsible engineering company, Bunting’s goal is to not only comply with this directive but also to mitigate the exposure of customers’ staff to as low a magnetic field as possible. This aim is central to our core design principles.

Understanding Stray Magnetic Fields

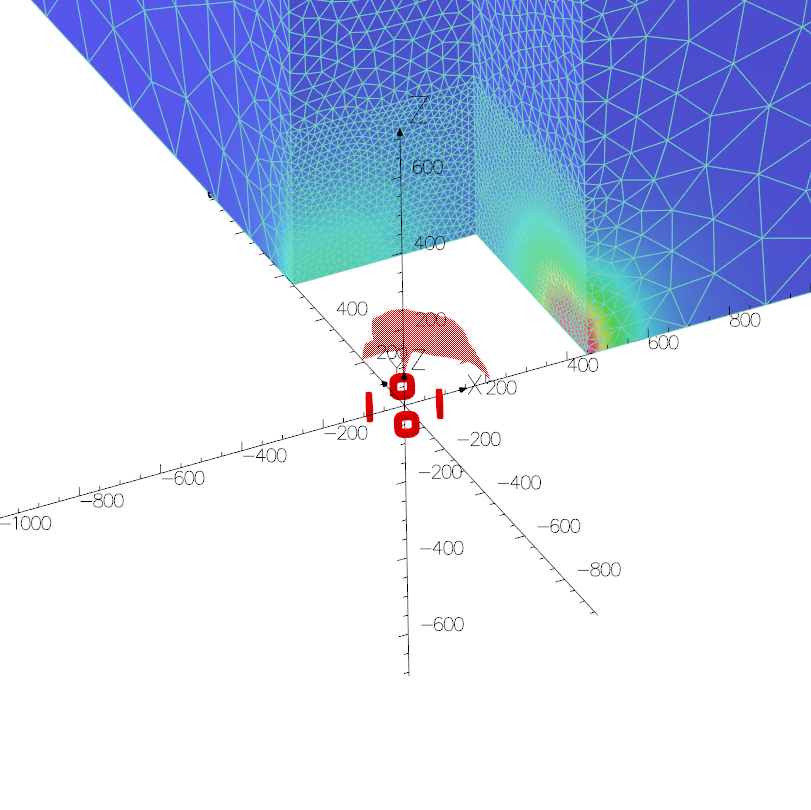

Figure 1 shows a 900 x 1100mm footprint of an automatic insertion and rotation system for the magnetisation of a multipole rotor. This would be the typical footprint of an automated system designed and built in-house at Bunting’s Berkhamsted facility in the United Kingdom. As with all modeling, there is symmetry in two planes so only 25% of the system is shown modeled. However, it applies to a full 3D environment.

- The blue shaded area represents the accessible area around the fixture in which people could walk;

- The deep red rings at the centre of the picture are the magnetising coils, embedded in a unique fixture design (not shown);

- The light red “cresting wave” is the field plot where the field is exactly 1mG;

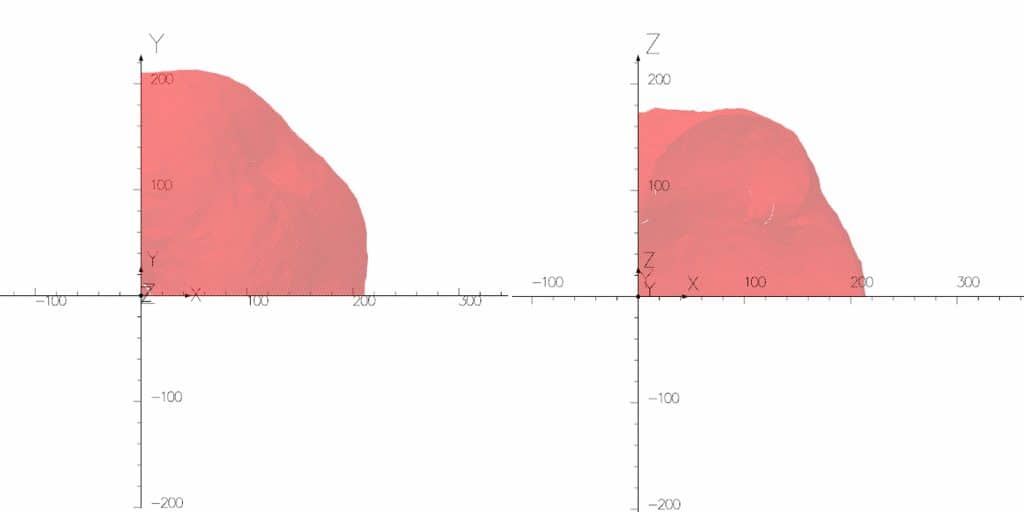

Figure 2 shows the magnetic field generated by the fixture (side and top view) and demonstrates the volume of space where the magnetic field decays to 1mG. This field spreads out (like a cresting sea wave) from the fixture and like all magnetic fields, the field halves each time the diameter doubles. A 500mm diameter sphere would be representative of the space, outside of which, the field is safe.

Detailed design and FEA analysis confirm that beyond this 450mm diameter sphere the magnetic field is less than 1mG. This would be considered safe not just for an operator, but also for the general public. This is 10-times safer than the industry standard requirement for operators and provides customers with the confidence that equipment purchased from Bunting exceeds all regulatory safety guidelines and directives.

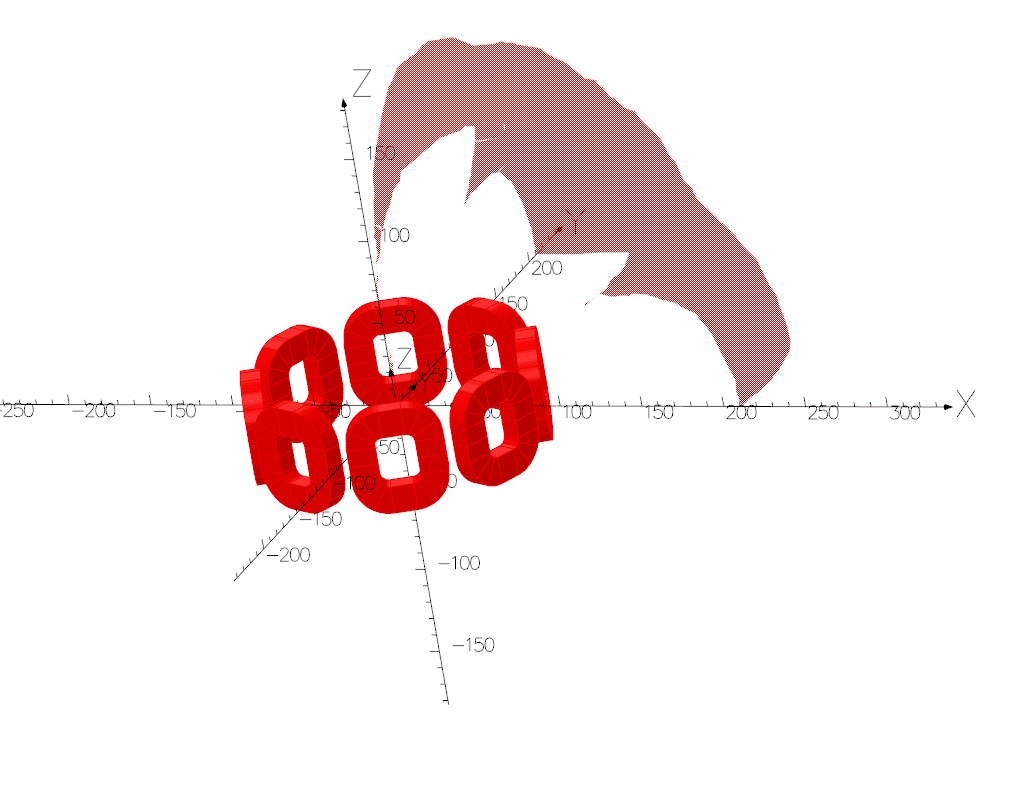

The nature of the cresting magnetic field wave is best depicted in figure 3.

With safety being a paramount factor in all manufacturing processes, Bunting is able to provide post-assembly magnetising systems for electric vehicles that provide both 100% polarity accuracy and inline safety checking for any operator or person entering that shop floor area.

Related Technical Articles

- Rare Earth Magnets in Electric Vehicle Motors

- Post Assembly Magnetisation for the Automotive Sector

- Magnet Health and Safety Advice

Magnet and Magnet Assembly Design

Bunting designs, manufactures and supplies a wide range of magnets, magnet setters, magnetisers, and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media