Manufacturing

Bunting Attains Bronze EcoVadis Sustainability Medal

Following the implementation of a series of sustainability initiatives, EcoVadis has awarded Bunting’s European operations a Bronze Sustainability Rating Medal. EcoVadis is one of the world’s largest providers of business sustainability ratings, creating a global network of more than 130,000+ rated companies. EcoVadis Medals and Badges recognise eligible companies that have completed the EcoVadis assessment…

Read MoreBunting Sponsors REPM 2023

Bunting has signed up as a gold sponsor of REPM 2023, the 27th international workshop on rare earth and future permanent magnets and their applications (3-7 September, University of Birmingham, UK). The biennial workshop is co-organised by SUSMAGPRO partner University of Birmingham and brings together scientists and engineers working on rare-earth permanent magnets and their…

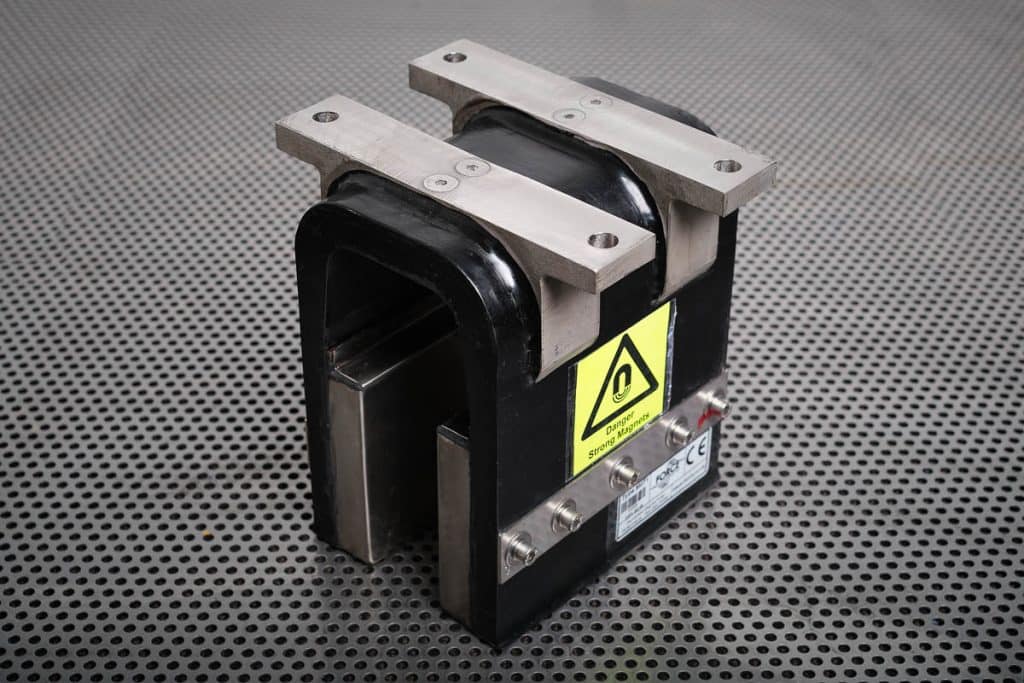

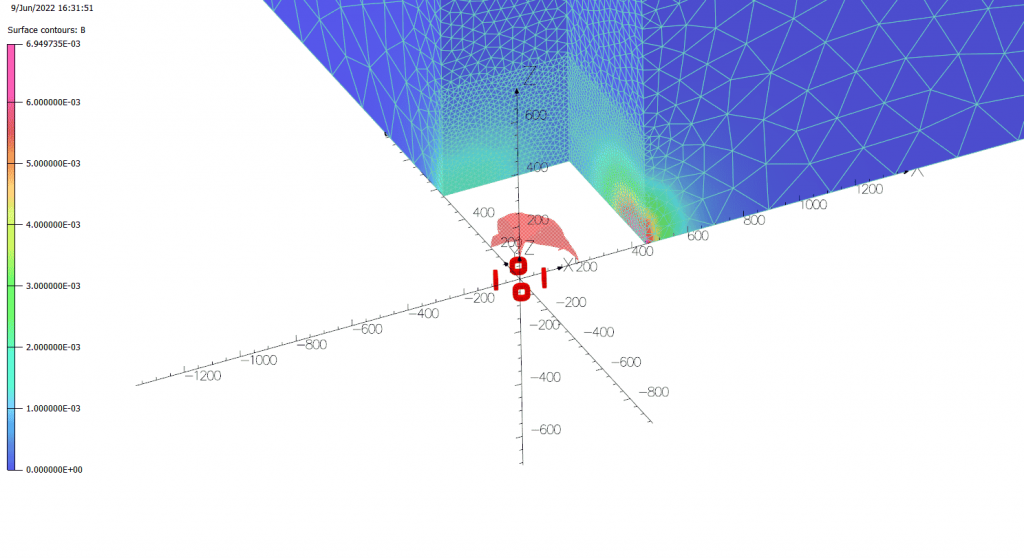

Read MoreBunting and Force Engineering Design Magnetic Rollercoaster Brake

Bunting and Force Engineering have collaborated to design and build a novel magnetic brake for use on rollercoasters. During the two-year project, the project team considered different permanent magnet arrangements required to generate the braking force needed to slow and stop a rollercoaster cart. The final design used high-power, low-weight neodymium magnets. As a leading…

Read MoreIndustrial Magnetiser for Ford Electric Vehicle Application

Bunting was successful in winning a bid to supply Ford Motor Company with an in house designed and built bespoke industrial magnetising system for use in a prototype build area. The industrial magnetising system charges and tests a magnet rotor assembly, which forms part of a new Transit electric power unit presently under development. Over…

Read MoreStray Magnetic Fields and Safety

Bunting is at the heart of the electrification program of the world’s vehicles. By producing magnetising systems that allow for genuinely error-free assembly and providing 100% inline testing, Bunting supports automotive and aerospace programmes looking to create new modes of travel and improve efficiency. Bunting is proud to support this sustainable engineering activity to provide…

Read MorePost-Assembly Magnetisation at Cenex LCV

Post-assembly magnetisation of permanent magnet rotors is the most cost effective and accurate way to produce these vital components for electric vehicle motors. Bunting is promoting such post-assembly magnetising manufacturing techniques on stand C4-607 at the Cenex LCV Event (7-8 September, UTAC, Millbrook, UK). The Cenex LCV Event focuses on low carbon and fuel cell…

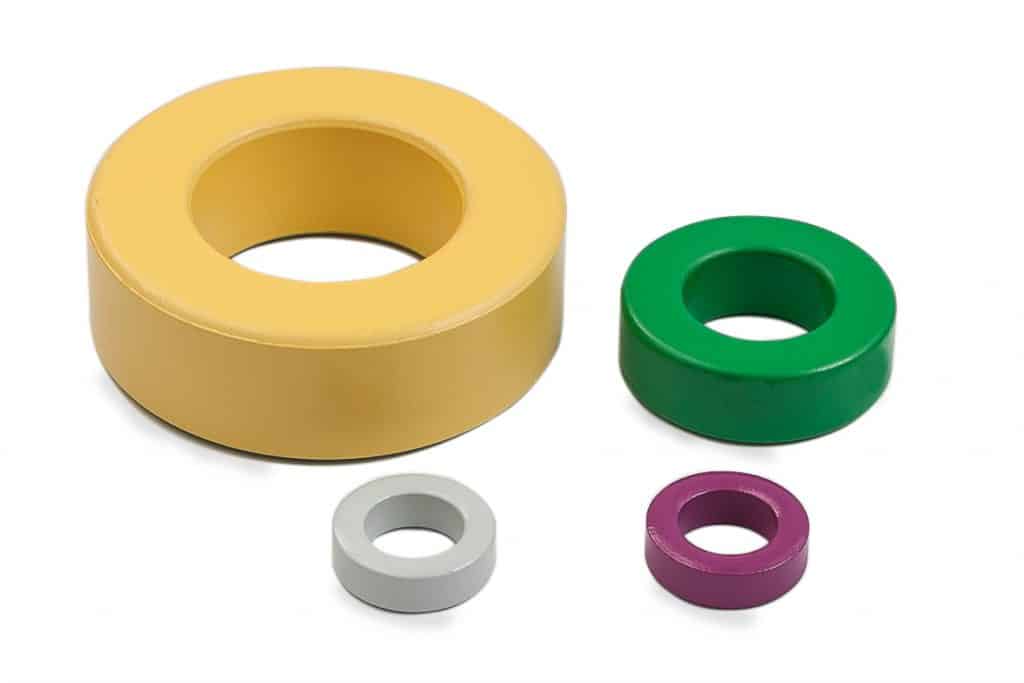

Read MoreExpanded Magnetic Solutions from MagDev at Southern Manufacturing 2022

Following the recent acquisition by Bunting, MagDev is exhibiting an expanded range of magnets, magnet assemblies, soft magnetics, and magnetising solutions on stand E190 at the 2022 Southern Manufacturing & Electronics show (Farnborough, UK, 8-10 February). MagDev is a member of the Bunting Group, which is one of the world’s leading designers and manufacturers of…

Read MoreBunting Magnet Test and Development Centre Investment

Bunting has invested in expanding their Test and Development Centre at Berkhamsted in the UK where they specialise in the design, test and build of a wide range of magnet and magnetic technologies. Bunting’s Berkhamsted operation is responsible for the design and manufacture of magnets, magnet assemblies, and magnetising equipment. The range of applications for…

Read MoreMagnetising and Magnet Technology at Coiltech Italia 2021

With a growth in sales of magnetising equipment and magnet assemblies into Italy in 2021, Bunting-Berkhamsted is exhibiting at the 12th Coiltech Italian 2021 international trade fair (stand 8-D27). Coiltech also hosts the World Magnetic Conference. The exhibition focuses on materials and machinery for the production and maintenance of electric motors, generators, power and distribution…

Read MoreImportance of Engineering Apprenticeships

When 21-year-old Ryan Haig-Godden finished wiring his first solo magnetiser panel project, it marked another important step in a three-year training journey and highlighted the importance of engineering apprenticeships. As Bunting is one of only a small number of global designers and builders of magnetisers, connecting the components within the magnetiser panel and building the…

Read More