Bunting-Berkhamsted 2021 Review

By Paul Fears | 13 December 2021

In another year dominated by the Covid-19 pandemic, a global shortage of materials, staff shortages, and transport delays matched with rising prices have created new challenges for manufacturing companies. Nevertheless, challenges often come with opportunities, especially with a growing importance for magnets as used in evolving green technology.

An Electric Future?

Throughout 2021, the world’s attention turned towards addressing climate change. Rare earth magnets play a key role in green technology, including electric vehicles. With 250 million electric vehicles expected on the world’s roads by 2030, our first blog of 2021 assessed rare earth magnets in electric vehicles and developments to increase the efficiency and performance.

We also launched our first new magnet product of 2021 in January. Neodymium Magnets with an Everlube coating prevents oxidation and deterioration of high-powered permanent neodymium rare earth magnets. This provides key benefits for applications in the automotive, aerospace and electronics sectors.

February marked the launch of another new product, the XGS33 grade of Samarium Cobalt rare earth magnets. The grade provides higher stability and magnetic performance at raised temperatures, which is ideal for projects where standard magnet performance is reaching the limit.

Expanding Design Project Capabilities

With an increase in the number of magnet development projects, particularly related to sensors and motors, our engineers developed a new Magnet Setter for AlNiCo magnets. The new magnet setter is capable of fully magnetising an AlNiCo magnet within a magnet assembly and then automatically knocking it back to the required value, all in one process. This enables precision magnetisation to meet the tight tolerances expected in industries such as automotive and aerospace.

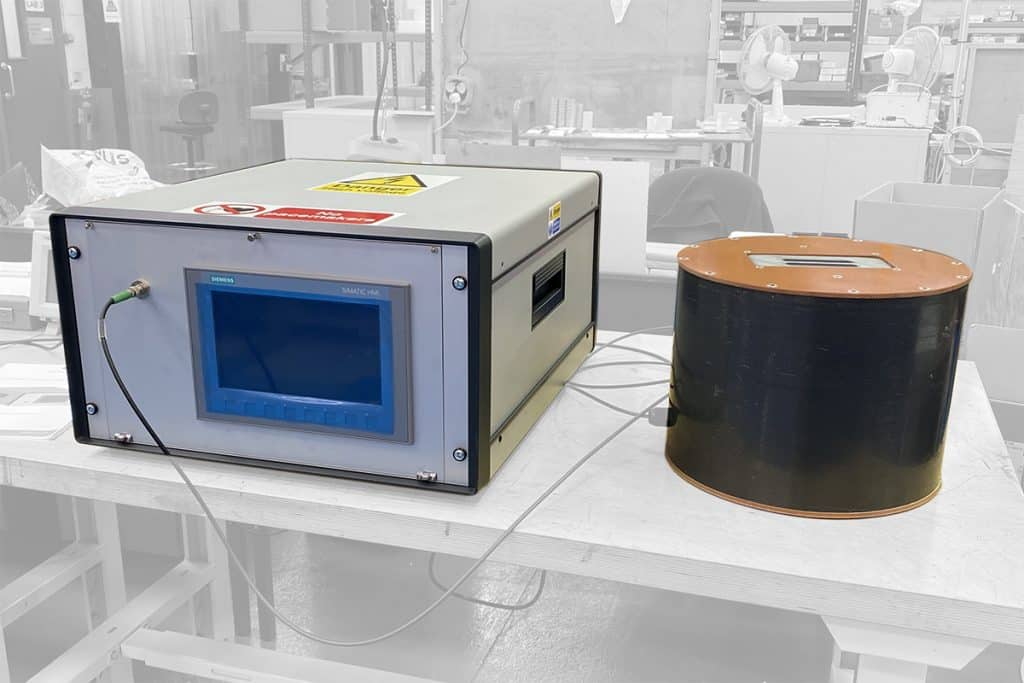

Later in 2021, we expanded our design project capabilities further by adding a new Magnet Setter demonstration unit to our magnet test and development centre. The BMCS-1510 Magnet Setter magnetises and sets Samarium Cobalt (SmCo) and AlNiCo magnets when connected to a compatible magnetising fixture. The magnet setter features a built in gaussmeter for measuring the magnetic field of the magnet during the setting process.

The expansion of our Magnet Test and Development Centre at Berkhamsted in the UK in 2021 was a consequence of the growth in development projects for magnets, magnet assemblies, and magnetising equipment. The investment means that the Berkhamsted facility is unique in the ability to provide total design services, from the selection of magnets material, design of magnet assembly, and magnetisation.

Investing in People Development

Staffing has been another hot topic of conversation for UK manufacturing in 2021. Investing in apprenticeships addresses the perceived shortfall in skilled people, especially in engineering. One of our apprentices, 21-year-old Ryan Haig-Godden marked another important step in a three-year training journey when he finished wiring his first solo magnetiser panel project. Bunting plans to expand their apprenticeship schemes across the European group.

Bunting’s policy of developing and promoting internal staff resulted in two promotions to the Berkhamsted management team in 2021. David Lewis took on the mantle of Quality Manager for all European facilities and David Hocking became Operations Manager at Berkhamsted.

The overseas business development strategy paid dividends in June with orders from Italy for a bespoke Industrial Magnetiser, complete with control cabinet, and a Magnet Setter. Stefano Maiaroli, manager of business development in Southern Europe, co-ordinated discussions between the Italian customers and Bunting’s engineering team to design the bespoke equipment.

In the same month, export business success was a focus with a leading European medical device manufacturer recognising Bunting’s high standard of provision with a top supplier award. Bunting supply approximately 20,000 Samarium Cobalt rare earth magnets annually for medical audio equipment. The project originated in 2016, when Bunting engineers worked closely with a team from the manufacturer to determine the optimum medical device magnet specification for the audio application.

We were also thrilled to announce the election of Matthew Swallow, Bunting’s Technical Product Manager, as Vice Chair of the UK Magnetics Society. Matthew was first elected as a committee member in 2018 and joins new Chair Ellie Galanis from Paragraf Ltd on the new executive committee.

A Return to Exhibitions and Conferences

Conferences returned in 2021, although many remained ‘virtual’. In April, we sponsored two events. The ‘Electric & Hybrid Aerospace Technology Virtual ‘Live’’ conference provided a platform for aerospace engineers, research academics, aircraft manufacturers, and others working on developing this ultra-low-emission, ‘green’ transportation technology. At the UK Magnetics Society’s ‘Magnetisation & Measurement Event’, we presented a paper on the advantages of post-assembly magnetisation of permanent magnet rotors.

Our first post-Covid exhibition was the Cenex-LCV Event at UTAC Millbrook Proving Ground, Bedfordshire, UK in September. At the same time, we exhibited for the first time at Coiltech Italia. Both proved to be exceptionally successful and it was great to be back meeting customers face-to-face.

MagDev Acquisition

In October, we announced the acquisition of UK-based magnet and magnet assembly manufacturer MagDev Ltd. MagDev is a leading custom magnets and industrial magnets manufacturer specialising in supplying permanent magnets, magnetic assemblies, and soft magnetic solutions in various shapes, sizes, and grades, with magnetic properties tuned to specific applications. The extended product portfolio and additional magnet engineering knowledge confirmed Bunting’s premier position in the European magnetics sector.

As with many raw materials, the price of magnet material has seen volatility in 2021. Through the year, we have been tracking the price of materials used in the manufacture of both Neodymium rare earth and Ferrite. The outlook remains uncertain and we intend to keep customers fully informed of future trends through our regularly updated blogs.

“We [Bunting] continue to evolve, which is vital to maintain our position as a global leader,” explained Simon Ayling. “Investing in developing overseas business and our internal design capabilities provides customers with unrivalled project support. The exciting acquisition of MagDev expands our range of magnetic solutions, especially in relation to soft magnet materials. We are well positioned for 2021 and will continue to evolve.”

Related Technical Article

Magnets, Magnet Assemblies and Magnetising Equipment

Bunting designs, manufactures and supplies a wide range of magnets, magnet setters, magnetisers, and magnet assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media