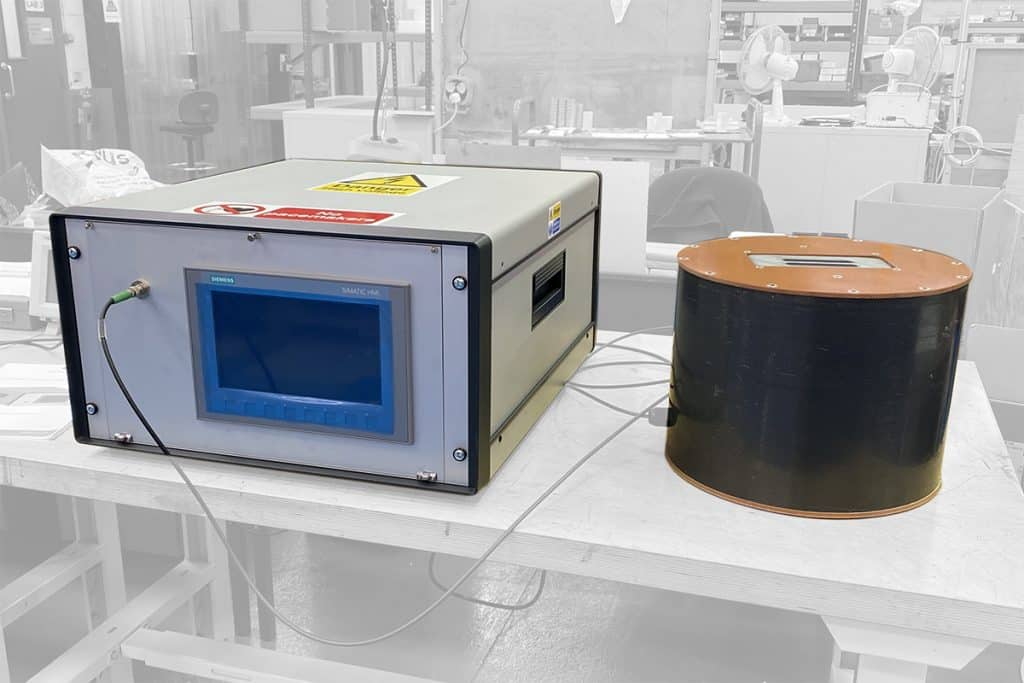

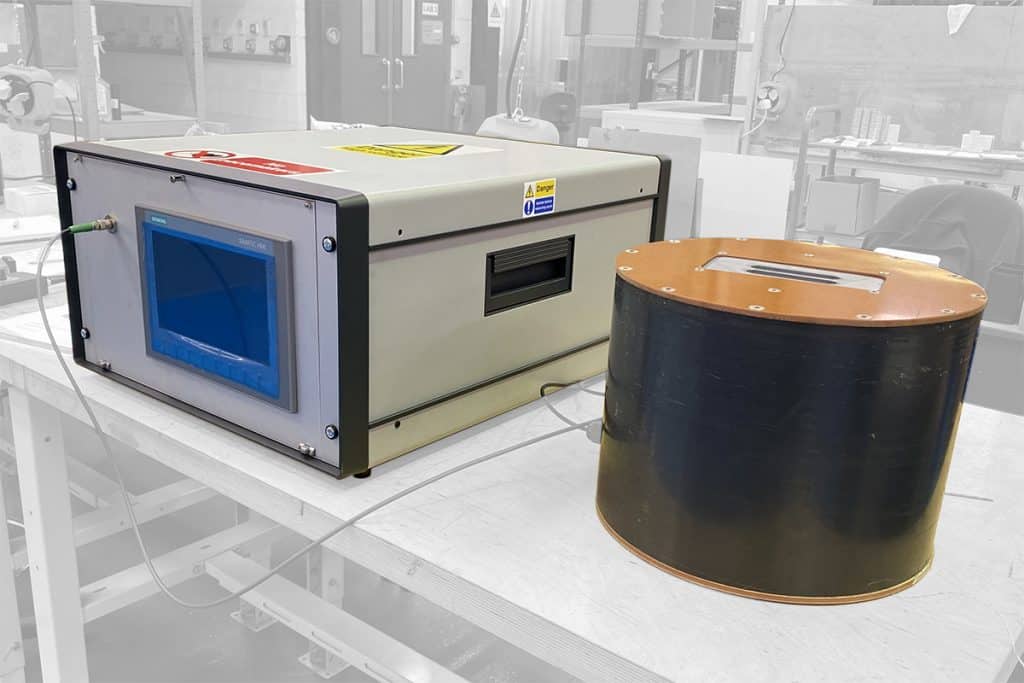

New Magnet Setter Demonstration Unit

By Paul Fears | 09 August 2021

In response to an increase in magnet design projects, Bunting-Berkhamsted has added a new Magnet Setter demonstration unit to their testing house.

The BMCS-1510 Magnet Setter magnetises and sets Samarium Cobalt (SmCo) and AlNiCo magnets when connected to a compatible magnetising fixture. The magnet setter features a built in gaussmeter for measuring the magnetic field of the magnet during the setting process.

Magnet Setter Operation

When turning on the Magnet Setter and starting the operating cycle, a trio of capacitors is charged up to the maximum voltage. Once charged, the capacitors will automatically discharge through the magnetising fixture, initially generating a pulsed magnetic field inside the fixture bore and then switching to a damped sinusoidal pulse.

- Technical Product Information: BCMS Magnet Setters

The magnet setter demonstration unit has three modes of operation: MAG, DEMAG and AUTO.

MAG Only Mode

The magnet setter generates a current pulse with a rapid rising sinusoidal shape and exponential decay. This results in a unidirectional magnetising field of sufficient magnitude to fully saturate the magnet in the fixture.

DEMAG Only Mode

The resulting current pulse has a damped sinusoidal shape. This results in an oscillating demagnetising field which decays to zero.

AUTO Calibration Mode

The “AUTO” calibration mode combines both “MAG” and “DEMAG” modes into one automated function. Once initiated, the magnet setter automatically magnetises the magnet to saturation and then repeatedly applies increasing demagnetisation pulses until the magnetic field of the magnet equals a user specified value. If the magnet setter “overshoots” the required value, the process will repeat until the setting cycle is complete.

Magnet Setter Applications

The Magnet Setter demonstration unit is exceptionally versatile with the ability to charge any shape and size of magnet or magnet assembly to suit a given application.

Specific projects include:

- Setting AlNiCo and small SmCo sensor magnets to specific field values;

- Setting small SmCo and AlNiCo magnet assemblies to specific values to alleviate tolerance stacks;

- Setting the magnetic pull strength of AlNiCo magnets to specific values, ensuring the magnet is not too strong or weak;

- Thermal stabilisation alternative;

- Relay setting;

- Position magnet setting;

- Magnet Pairing for audio and flow sensing;

Magnet Technical Expertise

The addition of the Magnet Setter demonstration unit further expands the technical capabilities of the Bunting magnet research and development team. The magnet experts at Bunting-Berkhamsted provide unrivalled technical support for the development of specific magnets, magnet assemblies and magnetising equipment for a diverse range of applications.

Presently in development is a new demonstration BMC5030 industrial magnetiser, replicating a system currently in operation having surpassed 4 million firing pulses. That equates to 1 firing per 6 seconds, 12 hours per day, 6 days per week for the last 2 years.

Related Technical Article

Magnet and Magnet Assembly Design

Bunting designs, manufactures and supplies a wide range of magnets, magnet setters, magnetisers, and magnetic assemblies. Many are bespoke for specific applications. For further information on any of the products mentioned in this article, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media