Bunting-Berkhamsted Review 2022

By Paul Fears | 12 December 2022

2022 turned out to be a rollercoaster of a year. Early post-pandemic positivity was quelled when Russia invaded neighbouring Ukraine, an unacceptable act of aggressive that caused the world’s economy to shudder. As a result, there was a rise in both material and energy costs. During the year both Neodymium and Ferrite raw materials rose steeply, with Neodymium reaching a record high in March 2022. Steadily material and fuel prices have fallen, but remain significantly higher than at the start of the year.

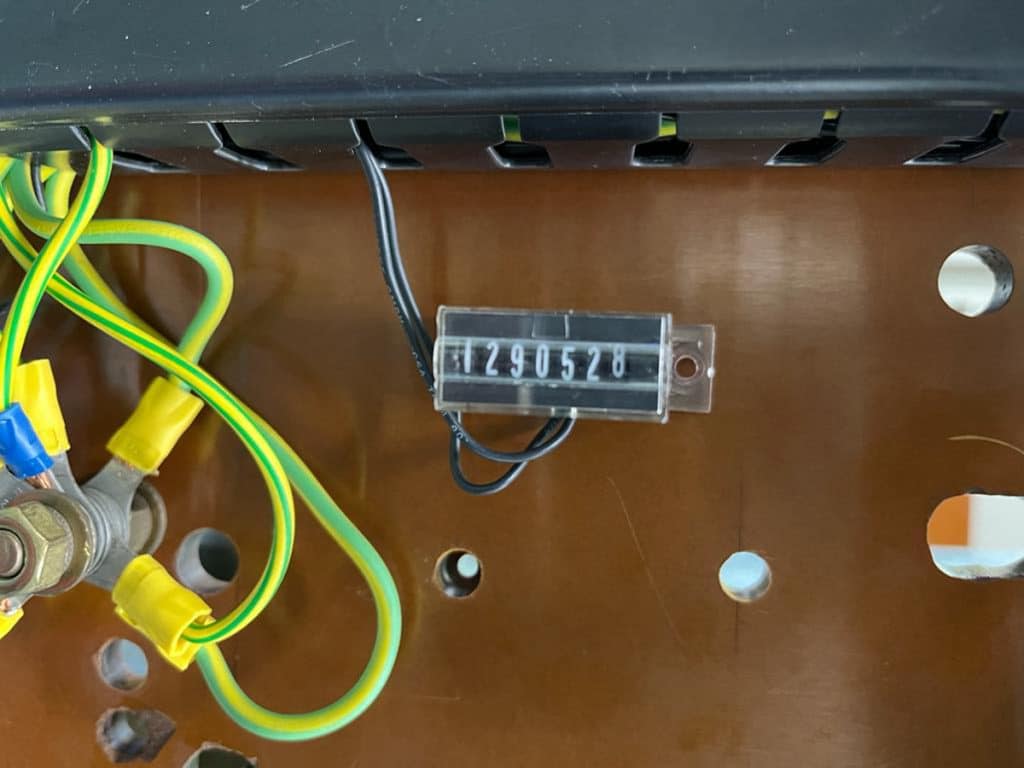

For Bunting-Berkhamsted there has been plenty of positivity in 2022. Our first case study in 2022 reported on a bespoke industrial magnetiser reaching 1.29 million discharges since being commissioned in 1997, equating to an incredible 1,000 per week. This highlighted the engineering design and build quality of our equipment.

In February, with the announcement of Dr Masato Sagawa being awarded the 2022 Queen Elizabeth Prize for Engineering (QEPrize), we looked back at the history of Neodymium Magnets. Dr Sagawa had developed and commercialised sintered rare-earth Neodymium Iron Boron magnet whilst working for Sumitomo Special Metals in Japan.

March turned out to be a very busy month, with a company acquisition, one exhibition, one conference and a visit to the UK by Bunting’s ex-CEO and Chairman Bob Bunting.

The visit by Bob Bunting was his first visit to the UK since before the pandemic. Bob took the opportunity to visit the recently expanded Redditch operation before travelling across to Berkhamsted, where he was shown the new layout of the factory floor.

Magnet applications stretch far and wide and Bunting’s diverse magnet product range was never more apparent than at the kbb show (March), a biennial event bringing together Europe’s leading kitchen, bedroom and bathroom designers and suppliers. Through the magnet online store eMagnets, Bunting supplies a wide range of magnetic catches for kitchen, bathroom and bedroom cupboards. Bunting exhibited at the show, with a focus on a new range of catches for Shaker kitchens.

The global Bunting Group’s growth continued in March with the acquisition of Gloucestershire-based powder milling and blending specialist Pilamec. Pilamec specializes in providing batch dry milling, screening and blending of organic and inorganic minerals for companies in industries as diverse as mining, refractories, foundries, recycling, and ceramics. The materials handled range from metals, slags to non-toxic chemicals, with investigation and test of any product, of any type, needing size reduction.

At the end of the month, Matthew Swallow, Bunting’s Technical Product Manager and Chair of the UK Magnetics Society reported on the Institute of Physics Magnetism 2022 conference (University of York, York, UK). The conference showcased a mixture of invited talks and submitted contributions across the breadth of fundamental magnetism.

In early April, the inaugural Coiltech Deutschland in Ulm, Germany brought together industry professionals involved in the production of electric motors, generators, transformers and coils. Bunting’s specialist range of magnets, soft magnetics, and magnetisers proved particularly interesting for attendees.

Our application story for the month looked at the role of AlNiCo pickup magnets in the development of modern electric guitar sounds. Guitar manufacturers and musicians discovered that even on the same guitar, switching out different AlNiCo alloys resulted in drastically different musical tones.

In 2021, Bunting acquired MagDev and in May 2022 their range of soft magnetic products was on show at the PCIM Europe exhibition in Germany. PCIM Europe is the world’s leading exhibition and conference for power electronics, intelligent motion, renewable energy, and energy management. At the exhibition, a significant proportion of the technology operates using magnetic forces. Bunting specializes in working with product designers to maximise the magnetic performance of a core.

“It was brutal” was Paul Fears’ comment after completing the 10nTaff challenge in early July. In just over 55 hours, Paul and a group of Dads climbed the five highest mountains in North Wales, then the five highest mountains in South Wales, before cycling 53 miles off-road from Brecon to Cardiff. The challenge raised over £40,000 for Tŷ Hafan, a Welsh registered charity that provided holistic palliative care for children who have life-limiting conditions and which has supported all the involved Dads’ families. Bunting was proud to sponsor the team.

There was exciting news in early July with the announcement that Matthew Swallow, Bunting’s Technical Sales Manager, had been elected as the Chair of the UK Magnetics Society on a 2-year posting. This follows his previous election as Vice-Chair in 2021.

At the end of the month, the latest case study focused on the remote monitoring of an Industrial Magnetiser locating in Italy. The control design enables Bunting’s UK-based engineers to have immediate access, which allows the quick identification and resolution of any issues.

Bunting returned to exhibit at the low-carbon vehicle Cenex-LCV Event in September, highlighting the advantages for post-assembly magnetisation of permanent magnet rotors used in electric vehicle motors. Matthew Swallow reviewed the 2022 event.

In September, Bunting announced the introduction of carbon neutral neodymium magnets. Following feedback from customers and staff relating to the environmental impact of magnet production, Bunting’s development team investigated requirements to start a carbon neutral journey. The first step involved making every sintered NdFeB permanent magnet sold online via Bunting’s e-Magnets ecommerce website carbon neutral. The cost of implementation was absorbed by Bunting and not passed onto the customer.

The technical feature in the month focused on stray magnetic fields and safety. Customers regularly ask about potential stray electromagnetic fields and the article explained the methods used by Bunting’s design engineers to ensure safety and compliance to the EU directive 2013/35/EU.

On October 1st, Bunting announced Robert Bunting’s appointment as President and CEO of the global Bunting group. Robert followed in the footsteps of his grandfather and father with his appointment as Bunting’s President and Chief Executive Officer. His father, Bob Bunting, assumed the position of Chairman.

Nearly every neodymium magnet will be plated or coated and, as the most powerful permanent magnet available, they are used in many different applications. October’s technical feature reviewed the different coatings available and the associated advantages and disadvantages.

With the global fuel crisis, November’s technical feature assessed the role of magnetic sensors in oil well drilling. In order to optimize drilling operations, oil and gas companies regularly use two types of magnetic sensors: fluxgate magnetometers and nuclear magnetic resonance sensors.

The final technical article of the year focused on the use of magnets in medical applications, specifically cochlear implants for people with hearing difficulties. Cochlear implants consist of external and internal components, which both use magnets. The external headpiece is worn in a similar manner to a hearing aid but operates very differently. The external hardware consists of three parts: the microphone, a speech processor, and a transmitting coil.

“Despite the gloomy economic backdrop, 2022 has been another successful year for Bunting-Berkhamsted,” said Simon Ayling, Bunting’s European Managing Director. “Through attending industry-specific exhibitions and conferences, we maintain our profile as a leading European magnetics company. Our success is a reflection of the dedication and commitment of our fantastic team at Berkhamsted, as well as the excellent support we get from both customers and suppliers. I am sure that there will be challenges in 2023, but we are perfectly positioned for another successful year.”

Bunting designs and manufactures a wide range of magnets, magnetic assemblies and magnetising equipment. Many are bespoke for specific applications. For further information on any of the products mentioned in this review, or for bespoke magnet assemblies and magnet designs, please contact us via:

Phone: +44 (0) 1442 875081

Email: sales.berkhamsted@buntingmagnetics.com

Via Bunting-eMagnets for online purchase of Magnets and Magnetic Technology

Follow us for all our latest news on Social Media