Posts Tagged ‘Neodymium Magnet’

Understanding Magnetic Permeance Coefficient

Firstly, it is important to understand that the maximum working temperature of a NdFeB magnet is not defined by the material grade! It is essential to calculate the magnetic permeance coefficient to establish what grade of material you need. The two examples compare the same magnet but with different thicknesses, one at 30mm and one at…

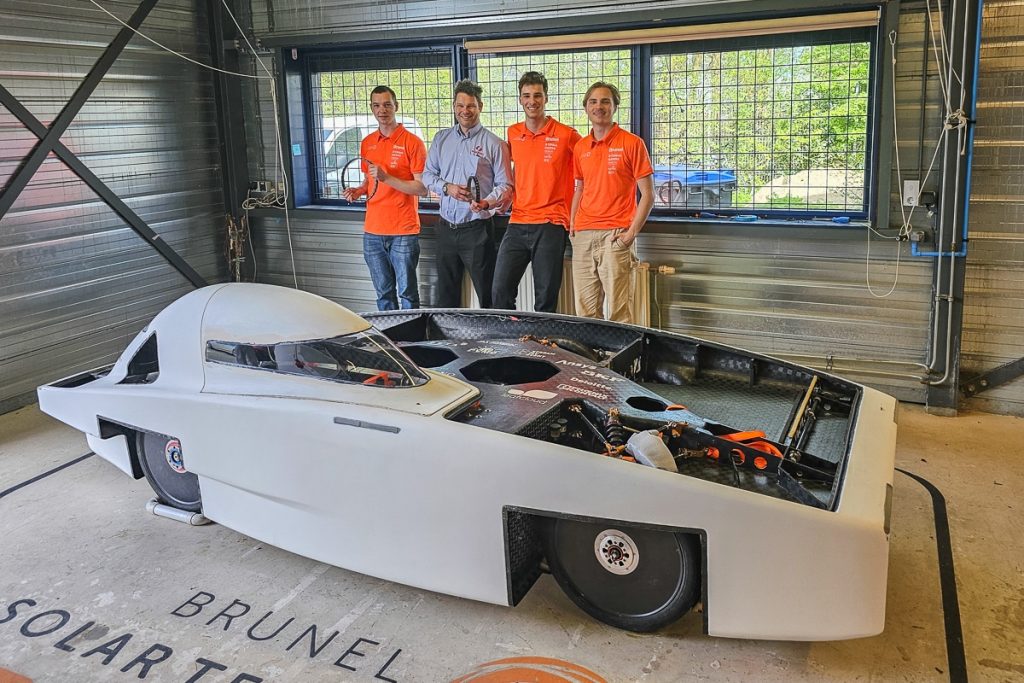

Read MoreThe Brunel Solar Team Technically Supported by Matthew Swallow

Matthew Swallow, Bunting’s Technical Product Manager, recently visited the Brunel Solar Team in The Netherlands as part of Bunting’s ongoing technical support on the solar car development project. Bunting is supporting the Brunel Solar Team with specialist magnets and technical support in the development of their Nuna 12S solar powered car. The Nuna 12S will…

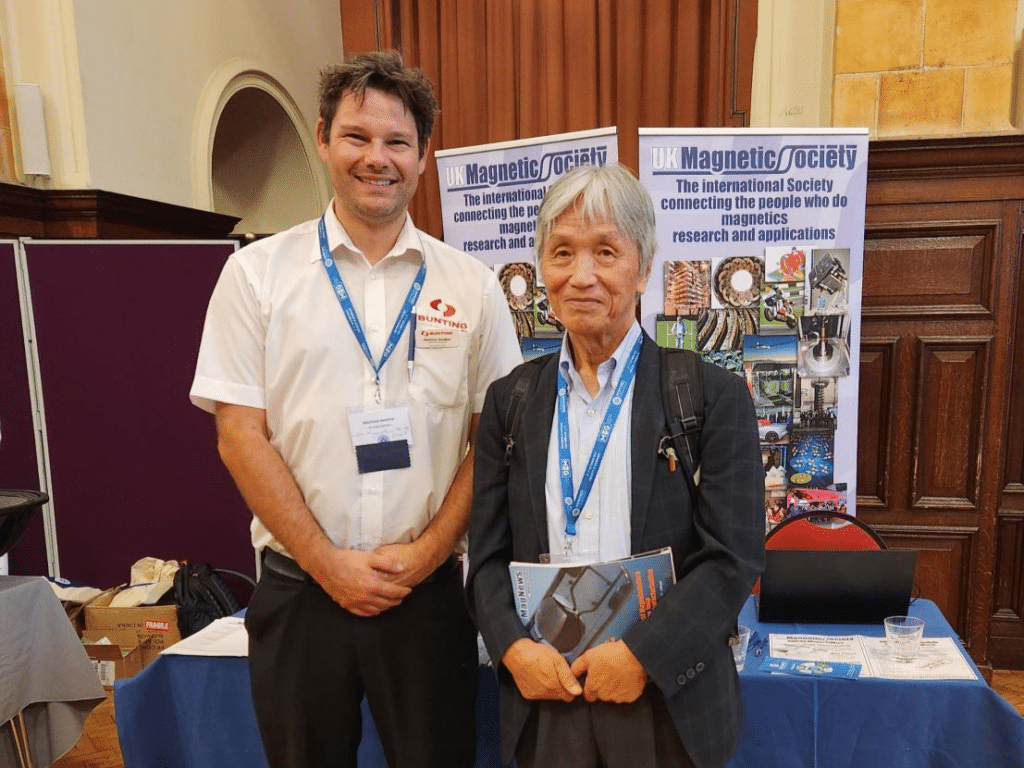

Read MoreA Review of REPM 2023

Matthew Swallow, our Technical Product Manager and the Chair of the UK Magnetics Society, reports on REPM 2023, the 27th international workshop on rare earth and future permanent magnets and their applications (3-7 September, University of Birmingham, UK). REPM is a biennial academic conference held and run by a hosting university or institution with the…

Read MoreMedical Magnet Spotlight: Magnets and Cochlear Implants

Magnets feature in a wide range of medical applications including heart pumps, surgical tools, hearing aids, and cochlear implants. A cochlear implant is a surgically implanted neuroprosthesis that provides a person who has moderate-to-profound sensorineural hearing loss with sound perception. Unlike hearing aids, which amplify sounds, cochlear implants bypass damaged areas of the ear and…

Read MoreCoatings for Neodymium Magnets

Nearly every neodymium magnet will be plated or coated and, as the most powerful permanent magnet available, they are used in many different applications. However, they possess physical characteristics that require them to be plated or coated in order to protect them from damage. In their raw form, neodymium magnets are quite brittle, and as…

Read MoreBunting Introduces Carbon Neutral Neodymium Magnets

In response to feedback from European customers, Bunting-Berkhamsted is the first magnet supplier to offer carbon-neutral sintered Neodymium Iron Boron (NdFeB) rare earth magnets sold online through the company’s Bunting-eMagnets ecommerce website. The manufacture of magnets such as NdFeB requires a considerable amount of effort and energy, from mining of the raw materials through to…

Read MoreThe History of Neodymium Magnets

The origin of the neodymium magnets dates back to 1885 when Carl Auer von Welsbach, an Austrian scientist and inventor, separated didymium into the new separate elements neodidymium (“new didymium”) and praseodidymium (“green didymium”). In time, the element names would change to neodymium and praseodymium. Neodymium (Nd) is the fourth member of the lanthanide ‘rare-earth…

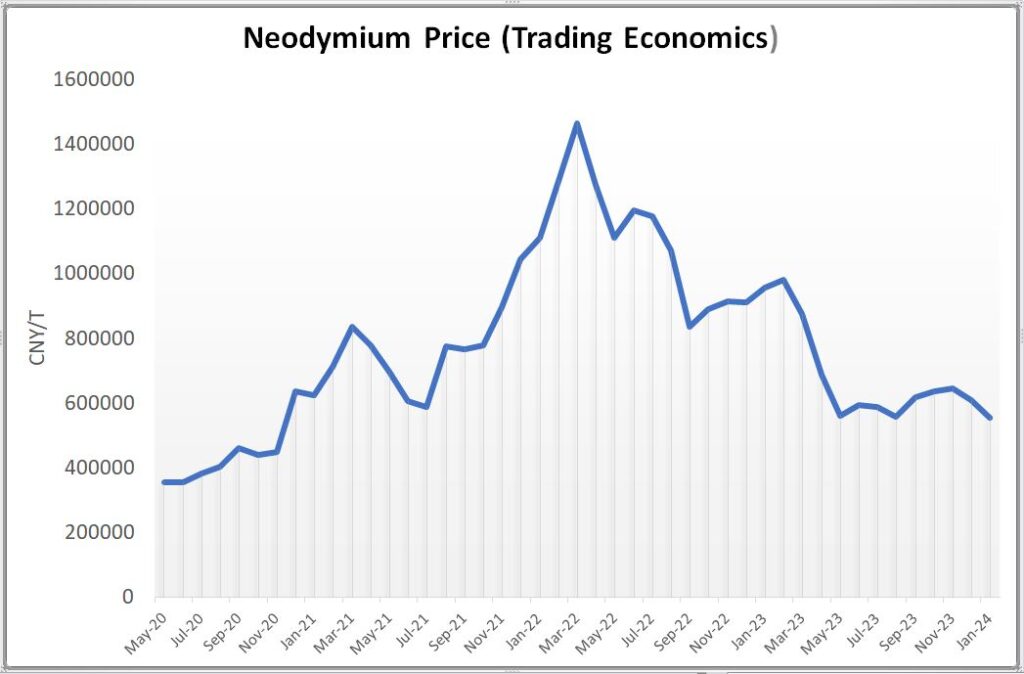

Read MoreNeodymium Price Trends

Updated 25th January 2024 On January 1st 2025, after rallying between August and November, the price of Neodymium fell to the lowest level since November 2020. The outlook remains uncertain, with further decreases likely in the short term. In 12 months, the price of Neodymium has fallen by 42%, way down on the peak price…

Read MorePermanent Magnet Motors Providing Key Benefits

Permanent magnet motors are electric motors using permanent magnets in addition to windings. Such motor designs are more efficient than induction motors or motors with field windings for certain high-efficiency applications such as electric vehicles and small electric motors such as found on drones and in car windshield wipers. Both AC and DC motors benefit…

Read MoreEverlube Coating Protects Neodymium Magnets

The new Everlube anti-corrosion magnet coating combats the increasingly arduous working environments for magnets and magnetic components. The Everlube coating prevents oxidation and deterioration of high-powered permanent neodymium rare earth magnets. The Everlube coating was originally developed as a brand of dry film lubricant products specifically designed to enhance and improve the performance of critical…

Read More