Magnetic Assemblies

Magnets and Magnet Assemblies for Defence Applications

Globally, permanent rare earth magnets play a major role in defence technology. They feature in a diverse range of applications including missile guidance systems, disk-drive motors in aircraft and tanks, satellite communications, and radar and sonar systems. Indeed, rare earth magnets are a critical component of a vast number of cutting-edge defence applications and a…

Read MoreBunting Sponsors Electric & Hybrid Aerospace Technology Virtual ‘Live’

The future of electric and hybrid aircraft technology is the focus for presenters and delegates at the Electric & Hybrid Aerospace Technology Virtual ‘Live’ conference (April 20 & 21, 2021). The 2-day online event provides a platform for aerospace engineers, research academics, aircraft manufacturers, others working on developing this ultra-low-emission, ‘green’ transportation technology. The move…

Read MoreBunting-Berkhamsted 2020 Review

On January 1st, nobody could have predicted the challenges businesses would face in 2020. Despite the restrictions and obstacles presented by the Covid-19 pandemic, companies adapted and continued to design and manufacture as they supported customers. December provides the ideal opportunity to reflect on many of Bunting-Berkhamsted’s positive news stories shared in 2020. A Positive…

Read MoreSensor Magnets

Sensors are used everywhere from vehicle engine management systems to Smartphones determining if the flip cover accessory is closed. Modern everyday life would be very different without sensors and the operation of many of these sensors rely on magnetism. As products evolve, so have the range and specification of sensor magnets. A magnetic sensor converts…

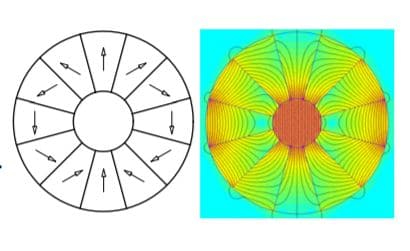

Read MoreReplicating True Radial Arc and Ring Magnets with Pseudo-Radial Arcs and Rings

The manufacture of anisotropic radially magnetised arcs and rings is significantly different to the production of diametrically magnetised rings and arcs. Radially aligned and magnetised anisotropic arcs and rings are only possible in fully dense sintered NdFeB and need a dedicated press tool and magnetising fixture and have a limited physical envelope (Max OD 85mm).…

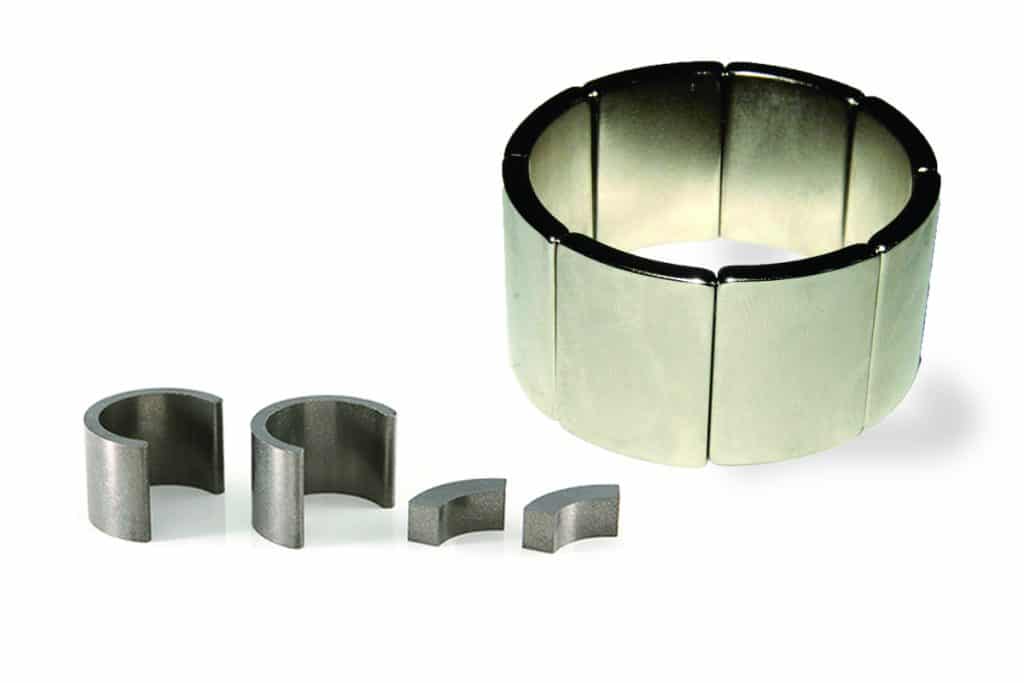

Read MoreSurface Mounted Arc Magnets

Bunting is capable of supplying almost any shape and size of a permanent magnet, but one of the most popular shapes is the arc. Arc magnets are used in a wide range of magnet assemblies, but in particular, surface mounted electric machines. There are four main types of arc magnets and these are: Each arc-type…

Read MoreBespoke Pot Magnet Design for Oil and Gas Application

An international Oil and Gas company turned to Bunting when investigating designs for a novel magnetic system to act as a pressure relief valve. The Pot Magnet assembly design requirements were complex with a number of significant technical challenges. The initial design evaluation identified that the bespoke magnet assembly would be based on a simple…

Read MoreCarbon Fibre Containment for Magnetic Rotors

Magnetic rotors are used in a wide range of applications including motors, generators, alternators and Eddy Current Separators. These rotors spin at very high speeds and a key design consideration is ensuring that the motors do not become detached from the magnet carrier. One of the key design considerations is the resultant centrifugal force. Centrifugal…

Read MoreMultipole Magnetic Rotor for Aerospace

Bunting has secured an order for the supply of 300 multi-pole Samarium Cobalt (SmCo) magnetic rotors annually to a prominent aerospace customer. The magnetic rotor order was placed at the end of 2019 with deliveries starting in 2020 and running for 10 years. The Bunting engineering team has worked with this aerospace customer for a…

Read More1200 Alnico Magnet Assemblies

Magnets and Magnetic Assemblies are a key component in many industrial sensing applications. Typical Magnetic Sensor applications include contact-less current sensing, linear and angular position, and rotation sensing. The Magnetic Assembly The Bunting engineering team designed the bespoke magnetic assembly for a specific customer application. The magnetic assembly consists of: Alnico ring magnet; Steel core; The…

Read More