Posts Tagged ‘Magnetising’

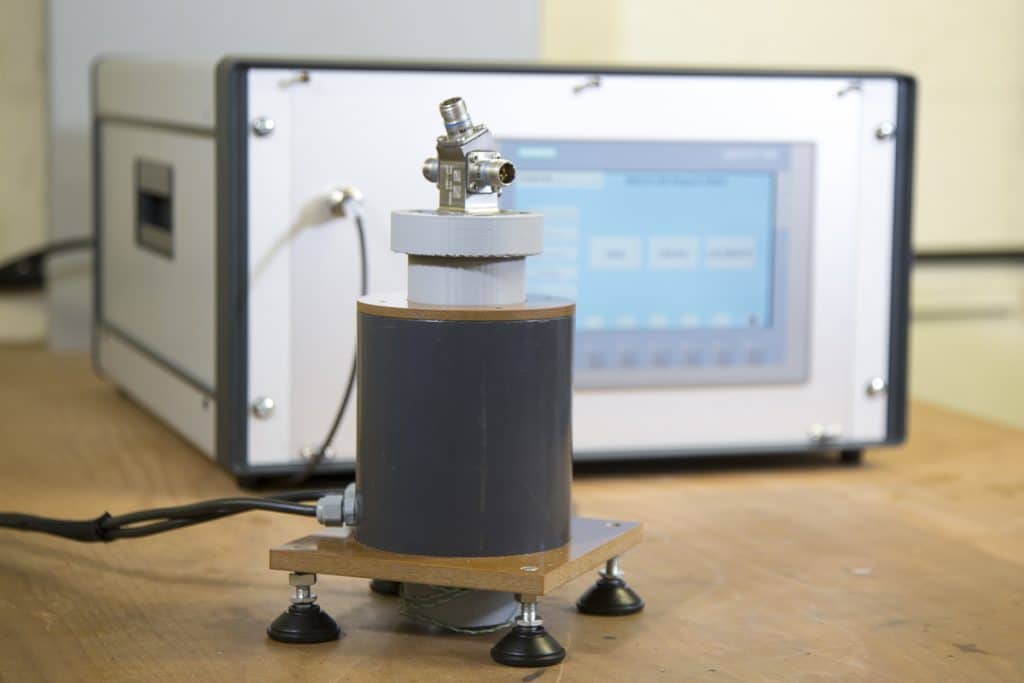

Post-Assembly Magnetisation at Cenex LCV

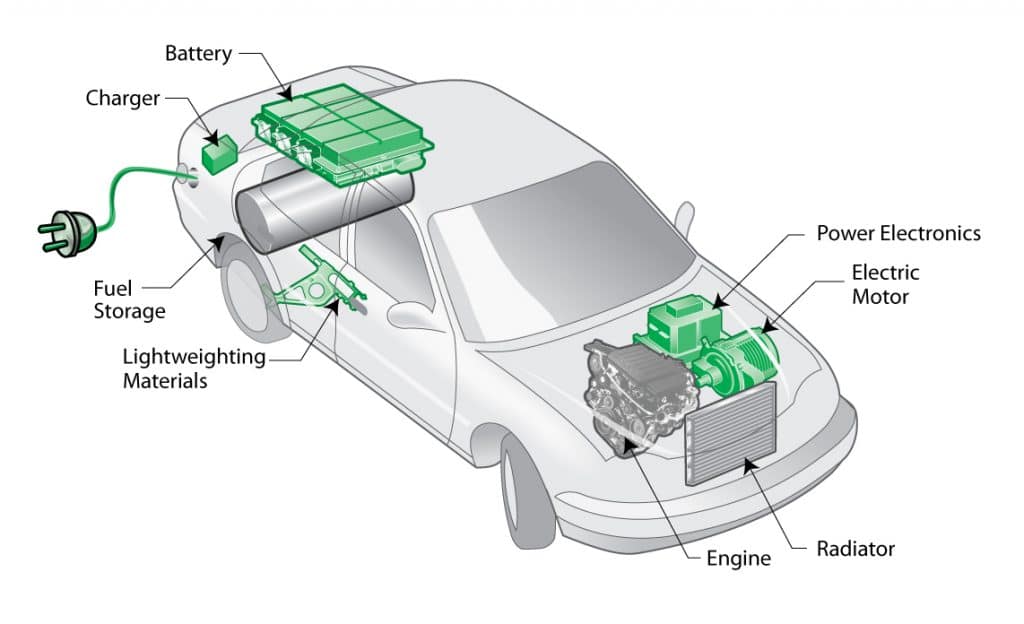

Post-assembly magnetisation of permanent magnet rotors is the most cost effective and accurate way to produce these vital components for electric vehicle motors. Bunting is promoting such post-assembly magnetising manufacturing techniques on stand C4-607 at the Cenex LCV Event (7-8 September, UTAC, Millbrook, UK). The Cenex LCV Event focuses on low carbon and fuel cell…

Read MoreRemote Magnetiser Monitoring and Problem Solving

Bunting has designed, manufactured, and supplied a large Magnetiser and light-guarded Magnetising Fixture to an Italian electronics company. Prior to despatch, the equipment was subject to a comprehensive two-day factory acceptance test with the customer. During the factory acceptance tests (FAT), Bunting’s commissioning engineers liaised with every stakeholder at the customer, checking on the operating…

Read MoreRecord Year for Magnetising Equipment Sales

Sales of Magnetising Equipment in 2021 hit an all-time record high for Bunting’s Berkhamsted, UK operation. The success is the result of ongoing development of a wide range of bench-top and industrial magnetisers, as well as magnet setters. Magnetiser Development Bunting is unique as a company designing and manufacturing both magnetising equipment and magnets. The…

Read MoreMagnetising Fixture Winding for Magnet Ring Sensor Project

Bunting’s engineering team work with companies on many magnet product designs, from concept through to manufacture. This project focused on the feasibility of designing, manufacturing, and supplying a permanent magnet ring to produce a sinusoidally varying flux density waveform for a sensor application. A sine wave or sinusoid is a mathematical curve that describes a…

Read MoreMagnetising and Magnet Technology at Coiltech Italia 2021

With a growth in sales of magnetising equipment and magnet assemblies into Italy in 2021, Bunting-Berkhamsted is exhibiting at the 12th Coiltech Italian 2021 international trade fair (stand 8-D27). Coiltech also hosts the World Magnetic Conference. The exhibition focuses on materials and machinery for the production and maintenance of electric motors, generators, power and distribution…

Read MoreAlNiCo Magnet Setter Development

Bunting engineers have developed a new Magnet Setter for AlNiCo magnets. AlNiCo Magnet Properties AlNiCo’s relatively low coercive force (Hc) means that the magnet material is easily magnetised to saturation, as well as fully or partially demagnetized by external fields. This makes an AlNiCo magnet easy to magnetise when part of an assembly, but could…

Read MoreMagnets and Magnetisers at Cenex LCV 2019

Grain Boundary Diffused Neodymium Magnets, Magnetisers and Magnet Setters are the focus for Bunting on stand C109 at this year’s Cenex LCV show (4th – 5th September, Millbrook, Bedfordshire, UK). Cenex-LCV is the UK’s premier low carbon vehicle event. The show features an extensive seminar programme and the opportunity to ride & drive the latest…

Read MoreBespoke Magnetiser for Electronics Application

High strength magnets (e.g. Neodymium Rare Earth) are a vital part in many everyday electric appliances. Charging those small magnets for use in electronics applications often requires a high degree of accuracy. One typical example is where the magnet interacts with a sensor to confirm that a component is correctly in place. Subsequently, Bunting designed…

Read More